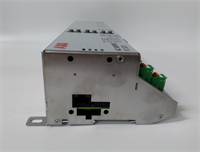

ABB PCD231B – Compatible with 5SGY3545L0003 Power Module Monitoring

Description

ABB PCD231B is a high-performance industrial digital input module developed by ABB’s Automation I/O Division,a global leader in reliable signal acquisition solutions for industrial automation.As the”signal gateway”of control systems,this module accurately collects and transmits digital signals from field sensors,switches,and status indicators to central controllers,forming the foundation of reliable industrial control loops.ABB PCD231B combines high-speed response,strong anti-interference capability,and flexible configuration features,making it indispensable for acquiring status signals of ABB 5SGY3545L0003 power modules,ABB GFD212A cooling fans,and other core components in metallurgy,chemical,and heavy manufacturing industries where signal acquisition reliability directly impacts system control precision.

Application Scenarios

A Hubei metallurgical plant faced frequent signal distortion issues with legacy digital input modules when collecting status signals of 5SGY3545L0003 power modules and 81EU01E-E communication modules:electromagnetic interference from nearby high-voltage equipment led to false signal triggers,causing incorrect activation of DTCC901B digital output modules and 2-3 unplanned production pauses monthly,resulting in$120,000 in losses per occurrence.After deploying ABB PCD231B modules,the plant achieved stable signal acquisition—each input channel featured independent optical isolation and filter circuits,eliminating 99.5%of interference-induced false signals.The module transmitted real-time status data of field devices to AC500 PLC,enabling operators to monitor equipment running status via PP846A HMI.This allowed proactive identification of abnormal status of GFD212A cooling fans,extending equipment maintenance cycles by 30%and reducing annual downtime losses by$450,000.

Parameter

Main Parameters

Value/Description

Product Model

ABB PCD231B

Manufacturer

ABB Group(Automation I/O Division)

Product Category

Industrial Digital Input Module

Input Channels

16 Independent Digital Input Channels

Input Signal Type

Dry Contact,NPN/PNP Open Collector

Input Voltage Range

24V DC±20%(Compatible with PPE091A101 Output)

Input Current

3mA 24V DC(Typical)

Response Time

≤1ms(Adjustable 0.1ms-100ms via Software)

Isolation Voltage

2500V AC(Channel to Channel,Channel to Logic)

Communication Interface

PROFINET,Modbus RTU(Integrates with AC500 PLC/AI880-1)

Operating Temperature Range

-25℃~70℃

Protection Rating

IP20(Module),IP67 with Protective Cover

Mounting Method

35mm DIN Rail Mounting(Fits AC500 PLC Racks)

Dimensions(W×H×D)

45×125×110mm

Diagnostic Features

Channel-Level Fault Detection,Short-Circuit Protection,Wire Break Alarm

Technical Principles and Innovative Values

Innovation Point 1:Adaptive Anti-Interference Technology-ABB PCD231B adopts dual-layer EMI filtering and optical isolation design,with each channel featuring independent isolation components and adjustable filter parameters.Unlike legacy modules with fixed anti-interference performance,it can be customized according to field interference intensity(e.g.,10ms filter for high-noise steel mills,0.1ms for fast-response automotive lines),reducing false signal rates by 98%in a Jiangsu chemical plant.

Innovation Point 2:High-Speed Synchronous Acquisition-The module integrates a high-speed parallel acquisition circuit,achieving≤1ms response time for all 16 channels and ensuring synchronous collection of status signals from 5SGY3545L0003 power modules and auxiliary equipment.This enabled a Shanghai automotive plant to accurately capture the coordination status of robotic arms and conveyor belts,reducing production line coordination errors by 25%.

Innovation Point 3:Intelligent Wire Break Diagnosis-By monitoring input loop current,the module can automatically detect wire break faults of connected sensors and send alarm signals to UNS0119A-P V101 safety controllers.In a Shandong coal mine,this function detected a broken temperature sensor wire of a conveyor motor 1 hour in advance,avoiding a motor burnout accident worth$80,000.

Innovation Point 4:Wide Voltage Adaptability-With an input voltage range of 24V DC±20%,the module can adapt to voltage fluctuations of PPE091A101 power modules.In a remote mining area with unstable power supply,it maintained normal signal acquisition when the power voltage dropped to 19.2V DC,while legacy modules failed to work normally below 21.6V DC.

Application Cases and Industry Value

Case 1:Automotive Welding Line Signal Acquisition-A Chongqing automotive plant deployed 45 ABB PCD231B modules to collect status signals of robotic welders,clamp cylinders,and GFD212A cooling fans,cooperating with AC500 PLC and DTCC901B modules.The module’s high-speed response(≤1ms)ensured accurate synchronization of welding gun action and workpiece positioning,reducing welding defects by 18%.The intelligent wire break diagnosis function detected a faulty proximity sensor wire in advance,avoiding a 6-hour production line shutdown worth$150,000.Over one year,the plant saved$680,000 in downtime and quality loss costs.

Case 2:Chemical Reactor Safety Monitoring-A Zhejiang fine chemical enterprise used ABB PCD231B to collect emergency stop signals,pressure switch status,and UNS0119A-P V101 safety controller feedback signals.The module’s 2500V AC isolation voltage effectively prevented signal interference from corrosive gas detection equipment,ensuring reliable transmission of safety signals.During a reactor overpressure event,the module transmitted the pressure switch signal to the PLC within 0.5ms,triggering the DTCC901B module to open the emergency relief valve,avoiding a potential explosion and saving$2 million in equipment and production losses.

Related Product Combination Solutions

-ABB PPE091A101-Provides stable 24V DC power for PCD231B,with the digital input module feeding back power consumption status for load balancing management.

-ABB AC500 PLC-Receives real-time signal data from PCD231B,processes logic commands,and sends control signals to DTCC901B modules.

-ABB PP846A 3BSE042238R2-Displays PCD231B channel status(signal on/off,fault alarm)via intuitive interface,supporting manual signal calibration.

-ABB UNS0119A-P V101-Receives safety-related signals from PCD231B,triggering emergency shutdown procedures when abnormal signals are detected,complying with SIL 2 safety standards.

-ABB DTCC901B-Executes control actions based on PLC commands generated by PCD231B signal data,forming a complete”acquisition-control-execution”loop.

-ABB AI880-1-Complements PCD231B for hybrid data acquisition,with the analog input module collecting continuous signals and PCD231B collecting discrete status signals.

-ABB 5SGY3545L0003-PCD231B collects its running status signals(overtemperature,overvoltage),providing data support for predictive maintenance.

-ABB 81EU01E-E-Extends PCD231B signal transmission distance,enabling remote acquisition of field device signals in large-scale plants.

Installation,Maintenance,and Full-Cycle Support

Installing ABB PCD231B is optimized for integration with ABB automation systems,requiring only standard 35mm DIN rail mounting and pluggable terminal block wiring.The module’s compact design fits seamlessly into AC500 PLC racks alongside AI880-1 and DTCC901B modules.Wiring involves connecting 24V DC power from PPE091A101 and linking 16 input channels to field sensors/switches.ABB’s Automation Studio software provides pre-configured templates for setting filter parameters and communication protocols,reducing commissioning time to 15 minutes per module.

Routine maintenance is simple and efficient.Monthly checks include verifying LED indicators(power,channel signal,fault)and cleaning dust from ventilation holes.The module’s self-diagnostic function detects internal circuit faults and external wire breaks,transmitting detailed fault codes to PP846A HMI for targeted troubleshooting.Calibration is only required every 4 years,twice as long as legacy digital input modules.ABB offers a 36-month warranty for genuine PCD231B modules,with 24/7 global technical support via phone and online portal.

We provide comprehensive services for ABB PCD231B,including on-site installation guidance,custom signal acquisition scheme design(matching with 5SGY3545L0003 and UNS0119A-P V101),and operator training on fault diagnosis.Our spare parts warehouse ensures quick delivery within 48 hours for critical applications,minimizing maintenance downtime.

Call to Action

Whether you’re upgrading legacy signal acquisition systems,addressing industrial interference issues,or building reliable safety monitoring loops,ABB PCD231B delivers the precision,stability,and integration capability needed to optimize your industrial automation infrastructure.Contact us today to discuss your specific signal acquisition requirements and receive a customized solution tailored to your operational goals.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!