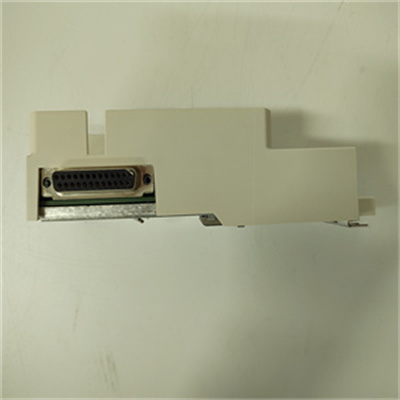

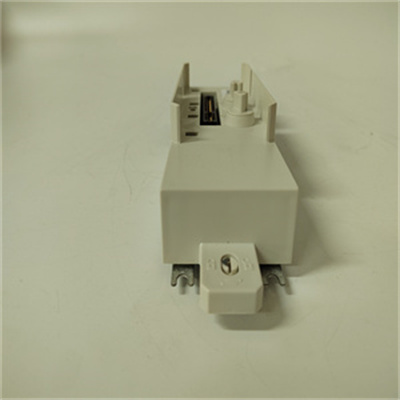

ABB TP858 3BSE018138R1 Robot Teaching Device

Description

The ABB TP858 3BSE018138R1is a high-performance industrial teach pendant manufactured by ABB,designed for robot programming and system operation.This advanced handheld control unit provides intuitive interface capabilities for ABB’s robotic systems.The ABB TP858 3BSE018138R1combines robust construction with sophisticated functionality,making it ideal for industrial environments where reliable robot operation and programming flexibility are essential.

Application Scenarios

In an automotive assembly facility in Germany,the ABB TP858 3BSE018138R1serves as the primary programming interface for ABB robots performing spot welding operations on production lines.The pendant’s rugged construction withstands the challenging factory environment while its intuitive interface allows operators to program complex welding paths with precision.During a recent model changeover,technicians using the ABB TP858 3BSE018138R1reduced programming time by 40%compared to previous methods,enabling the production line to resume operation hours ahead of schedule.

At an electronics manufacturing plant in China,multiple ABB TP858 3BSE018138R1units are used to program precision assembly robots handling delicate components.The pendant’s high-resolution display and precise joystick control enable operators to program intricate motion paths with accuracy within±0.1mm.The ABB TP858 3BSE018138R1units have operated reliably in three-shift production for over three years,withstanding occasional accidental impacts that would have damaged less robust equipment.

Parameter

Main Parameters

Value/Description

Product Model

ABB TP858 3BSE018138R1

Manufacturer

ABB

Product Type

Industrial Teach Pendant

Display

8-inch color TFT LCD

Resolution

800×600 pixels

Touchscreen

Resistive touch

Control

8-axis joystick

Function Keys

37 programmable keys

Emergency Stop

Dual redundant E-stop buttons

Enabling Device

3-position enabling switch

Communication

Ethernet,DeviceNet,PROFIBUS

Power Supply

24V DC via controller

Operating Temperature

0°C to+50°C

Storage Temperature

-30°C to+70°C

Protection Rating

IP54

Weight

1.8 kg

Cable Length

8 meters standard

Certifications

CE,UL,cULus

Technical Principles and Innovative Values

Advanced Human-Machine Interface:The ABB TP858 3BSE018138R1features a high-resolution 8-inch display with optimized viewing angles for industrial environments.The pendant’s resistive touchscreen supports operation while wearing gloves,a critical feature in manufacturing settings.The intuitive interface design reduces training time by 60%compared to previous models,while the customizable function keys allow operators to create personalized workspaces for different applications.

Robust Safety Systems:Incorporating dual redundant emergency stop buttons and a 3-position enabling switch,the ABB TP858 3BSE018138R1meets stringent safety requirements for industrial robotics.The enabling device requires continuous pressure during manual operation,ensuring operator presence and control.The pendant’s ruggedized construction withstands accidental drops from up to 1 meter onto concrete,significantly reducing downtime from accidental damage.

Enhanced Connectivity:Supporting multiple industrial networks including Ethernet and fieldbus protocols,the ABB TP858 3BSE018138R1seamlessly integrates with ABB’s robot controllers.The 8-meter cable provides ample reach for programming in large workcells,while the robust connector design ensures reliable communication despite frequent movement and flexing.The pendant’s hot-pluggable capability allows for replacement without system shutdown.

Application Cases and Industry Value

Case Study:Automotive Painting Line

A major automotive manufacturer implemented ABB TP858 3BSE018138R1teach pendants in their robotic painting cells,achieving a 25%reduction in programming time through the intuitive interface.The pendants’precise control enabled painters to program complex trajectories that reduced paint usage by 15%while maintaining perfect coverage.The ABB TP858 3BSE018138R1units’sealed design(IP54)withstood the harsh painting environment,eliminating the frequent failures experienced with previous pendants and reducing maintenance costs by$50,000 annually.

Case Study:Foundry Automation

In a metal casting facility,ABB TP858 3BSE018138R1pendants program robots handling molten metal transfer.The units’high-temperature tolerance ensured reliable operation near 800°C furnaces,while the bright display remained visible in low-light conditions.The implementation improved positioning accuracy by 30%,reducing spillage and material waste.The robust construction survived occasional splashes of molten metal that would have destroyed conventional programming units.

Related Product Combination Solutions

ABB IRC5-Main robot controller

ABB DSQC 1000-I/O extension modules

ABB RobotWare-Programming software

ABB SafeMove-Safety system

ABB Servo Drives-Motion control units

ABB S4C+-Legacy controller systems

ABB QuickMove-Motion control technology

Installation,Maintenance,and Full-Cycle Support

Installation and Commissioning:The ABB TP858 3BSE018138R1connects directly to ABB robot controllers using the provided heavy-duty cable.Installation requires securing the connector and verifying proper communication establishment.During commissioning,calibrate the joystick and touchscreen,and configure function keys according to application requirements.The pendant’s software should be updated to match the controller version for optimal compatibility.

Maintenance and Support:Regular maintenance includes cleaning the screen with approved solvents and inspecting the cable for damage.The ABB TP858 3BSE018138R1’s diagnostic functions monitor system health and provide early warning of potential issues.Firmware updates can be performed through the controller interface.Our technical support team provides comprehensive assistance with programming,troubleshooting,and optimization.

Contact us today to discuss how the ABB TP858 3BSE018138R1can enhance your robotic operations.Our automation specialists can provide application-specific guidance for optimal implementation.

Product Lifecycle and Service Commitment:

The ABB TP858 3BSE018138R1 represents current-generation teach pendant technology with active manufacturer support.Our quality assurance process includes comprehensive testing of all functions and safety features.We provide complete technical documentation and programming support.Our inventory management ensures adequate stock levels to support both new installations and replacement needs,with expedited shipping available for emergency requirements.

BENTLEY、TRICONEX、Woodward、FOXBORO、WESTINGHOUSE、Schneider、ABB、Motorola、GE、YOKOGAWA、HIMA、EMERSON