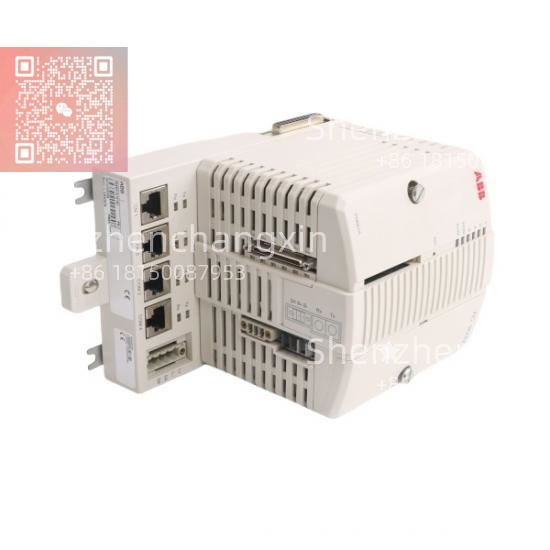

ABB PM864AK01 AC 800M Processor – Hot-Swappable, Extended Temp, Long Lifecycle

Description

The PM864AK01 (ABB order code 3BSE018161R1) is a high-reliability central processing unit (CPU) from ABB’s AC 800M controller family, engineered as the computational backbone of the System 800xA distributed control system (DCS). Designed for continuous, mission-critical process automation in industries like oil & gas, power generation, and chemicals, the PM864AK01 delivers deterministic logic execution, built-in communication redundancy, and seamless integration with S800 I/O—ensuring plant availability, safety, and operational efficiency.

Application Scenarios

At a North Sea offshore platform, unplanned shutdowns due to controller failures cost over $ 2 million per incident. The aging DCS used non-redundant CPUs with limited diagnostics. Engineers upgraded to dual PM864AK01 units in hot-standby redundancy. During a lightning-induced surge that fried the primary unit’s Ethernet port, the standby PM864AK01 took over in <200 ms—with zero process interruption. Operators monitored the switchover remotely via the built-in web server, while maintenance replaced the failed module during routine rounds. Over three years, the platform achieved 99.998% controller uptime, turning reliability into measurable ROI.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: True Hot-Standby Redundancy with State Synchronization – The PM864AK01 continuously mirrors application state, I/O data, and communication buffers to its redundant partner via a dedicated sync link, ensuring bumpless transfer during failure—critical for continuous processes like distillation or power generation.

Innovation Point 2: Embedded Web Server for Remote Diagnostics – Technicians can access real-time CPU load, memory usage, I/O status, and error logs via any standard web browser—eliminating the need for engineering software during troubleshooting.

Innovation Point 3: Unified Engineering in Control Builder Plus – The same environment configures logic (IEC 61131-3), HMI, alarms, and redundancy—reducing integration risk and lifecycle costs in large-scale DCS deployments.

Innovation Point 4: Long-Term Availability & Migration Path – ABB guarantees long product lifecycles and provides migration tools to newer AC 800M variants (e.g., PM866), protecting customer investment for decades.

Application Cases and Industry Value

A municipal wastewater treatment plant in Germany modernized its 20-year-old control system using PM864AK01 controllers paired with S800 I/O. The plant required 24/7 operation with minimal staff. Using the PM864AK01’s web interface, operators diagnosed a failing blower motor from home by reviewing trended analog input data and digital status—all without visiting the site. Over five years, maintenance visits dropped by 60%, and energy optimization logic running on the PM864AK01 reduced aeration power consumption by 18%. Regulators commended the system’s audit-ready event logging during environmental inspections.

Related Product Combination Solutions

CI854: Profibus DP communication module – enables connection to drives, valves, and remote I/O.

TU840 / TU854: S800 I/O baseplates – directly connected via optical or electrical ModuleBus.

PM865AK01: Higher-performance successor with faster scan and more memory—ideal for complex batch processes.

Control Builder Plus: Engineering suite – fully supports PM864AK01 configuration, redundancy setup, and firmware management.

System 800xA: Unified DCS platform – integrates PM864AK01 data into alarm management, historians, and asset performance tools.

TB820: Terminal blocks – provide secure field wiring for S800 I/O linked to PM864AK01.

ABB Ability™ Asset Performance Management: Leverages PM864AK01 diagnostics for predictive maintenance and OEE tracking.

Installation, Maintenance, and Full-Cycle Support

Installing the PM864AK01 involves mounting on DIN rail, connecting dual power feeds (for redundancy), linking to I/O baseplates via ModuleBus cables, and configuring IP addresses. Redundant pairs require a dedicated sync cable and mirrored network topology. Commissioning is performed in Control Builder Plus, which validates firmware, downloads application logic, and tests redundancy switchover.

Maintenance is simplified by comprehensive diagnostics: front-panel LEDs indicate RUN, STOP, I/O, and REDUNDANCY status. The web interface provides detailed fault logs, including last scan time and memory usage. In redundant mode, failed units are hot-swapped without process impact. We provide full lifecycle support—including firmware updates aligned with cybersecurity standards, long-term spare parts commitment, and migration planning to next-gen platforms.

Contact us for a customized solution—whether you’re building a new DCS, modernizing legacy infrastructure, or ensuring regulatory compliance in safety-critical operations, the ABB PM864AK01(3BSE018161R1) delivers industrial-grade reliability, seamless integration, and decades of proven performance where continuity is non-negotiable.