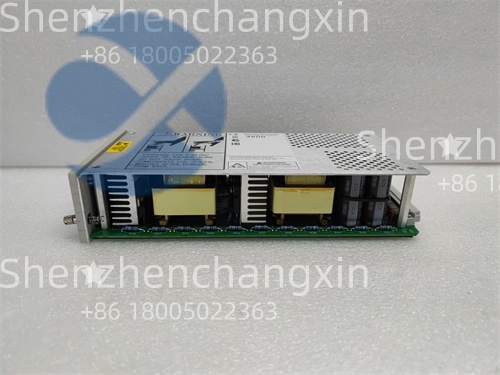

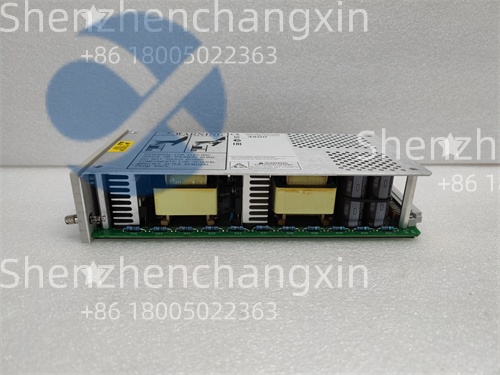

BENTLY 125680-01 | Vibration Monitoring Module

Description

The BENTLY 125680-01is a high-performance radial vibration monitoring module manufactured by Bently Nevada,a Baker Hughes business,for its industry-leading 3500 series machinery protection system.This specialized module serves as a critical interface for proximity probe systems,converting raw sensor signals into precise vibration and position measurements for protecting valuable rotating assets.

Application Scenarios

Picture a critical synthesis gas compressor in a petrochemical plant running 24/7.A sudden increase in shaft vibration,undetected,could lead to catastrophic bearing failure,resulting in weeks of downtime and millions in lost production.In this high-stakes environment,the BENTLY 125680-01acts as the vigilant guardian.Installed in a 3500 system rack near the compressor,it continuously processes signals from eddy-current proximity probes mounted on the compressor’s bearings.It doesn’t just measure vibration;it provides early warning by detecting subtle changes in the dynamic motion of the shaft(amplitude and phase),enabling maintenance teams to investigate issues during planned turnarounds rather than facing emergency shutdowns.Its role is pivotal in transitioning from reactive repairs to predictive maintenance,directly safeguarding operational continuity and capital investment.

Parameter

Main Parameters

Value/Description

Product Model

BENTLY 125680-01

Manufacturer

Bently Nevada(Baker Hughes)

Product Category

Radial Vibration Monitor Module

Compatible System

3500 Series Machinery Protection System

Channels per Module

Typically 2 channels(monitors two XY probe pairs for one radial position).Enables comprehensive radial vibration monitoring at a single measurement point.

Input Sensor Type

Compatible with Bently Nevada 3300 XL 8mm or 11mm Proximity Probes and proximitors.Industry-standard sensor interface for displacement measurement.

Measured Parameters

Vibration Amplitude(peak-to-peak in mils orµm),Phase(relative to a Keyphasor®reference),and Gap Voltage(average probe distance).Provides a complete picture of shaft dynamics.

Frequency Response

Typically 0.4 Hz to 10,000 Hz.Captures both slow-roll and high-frequency vibration components.

Dynamic Range

High(e.g.,120 dB).Accurately measures both very small and large vibration signals.

Alarm Outputs

Multiple programmable alert and danger alarm setpoints per channel.Triggers pre-warning and shutdown signals based on configurable thresholds.

Outputs

Buffered sensor signals,4-20mA proportional outputs,relay contacts.Provides data for DCS/PLC systems and direct trip circuits.

Keyphasor®Reference

Required input for phase measurement.Synchronizes vibration data to shaft rotation for diagnostic purposes.

Technical Principles and Innovative Values

Innovation Point 1:Dual-Channel Vector Measurement for Accurate Diagnosis.The BENTLY 125680-01doesn’t just report a single vibration level.Each module typically handles two orthogonal probes(X and Y)at a single radial plane.By processing both channels simultaneously,it can calculate the true shaft centerline position and orbit.This vector-based approach is crucial because it reveals the direction of vibration,which is a key diagnostic indicator for problems like unbalance(heavy spot),misalignment,or oil whirl.This rich data set,accessible via the 3500 system software,turns the module from a simple alarm device into a powerful diagnostic tool.

Innovation Point 2:Integration of Protection and Diagnostics.The module seamlessly blends mandatory protection functions with advanced condition monitoring.While its primary role is to trigger alarms and trips to prevent machine damage(protection),it also outputs continuous,high-fidelity vibration waveforms and processed parameters(1X,2X amplitude,phase).This allows the same hardware to feed both the safety-critical protection system and the plant’s predictive maintenance software,providing a single source of truth and eliminating the cost and complexity of separate systems.

Innovation Point 3:Robust Signal Integrity and Self-Diagnostics.Operating in electrically noisy plant environments,signal integrity is paramount.The BENTLY 125680-01incorporates high-quality filtering,isolation,and signal conditioning to ensure the measured vibration reflects true mechanical motion,not electrical interference.Furthermore,it continuously performs self-diagnostics,monitoring its own health,the integrity of the probe and cable system(via Gap Voltage),and the validity of the Keyphasor signal.This”watchdog”function ensures the protection system itself is always functional,maintaining the integrity of the safety loop.

Application Cases and Industry Value

Case Study:Steam Turbine Generator Protection in a Power Plant.A utility company was experiencing unexplained,non-repeatable high-vibration trips on a 300 MW steam turbine-generator.Traditional troubleshooting was inconclusive.Engineers utilized the detailed waveform and orbit data provided by the BENTLY 125680-01modules installed on the turbine bearings.Analysis revealed transient shaft motions characteristic of steam whirl,a stability issue caused by steam forces in the turbine seals,not a mechanical fault.Based on this precise diagnosis from the monitor’s data,the plant implemented an operational adjustment to steam conditions rather than a costly mechanical overhaul.This intervention eliminated the trips,securing hundreds of hours of additional generation annually.The case demonstrated how the 125680-01’s diagnostic capability transformed an operational nuisance into a solvable problem,preventing unnecessary maintenance and maximizing asset availability.

Related Product Combination Solutions

A complete machinery protection point using the BENTLY 125680-01requires several synergistic components:

BENTLY 330103-00-05-10-02-00:An 8mm or 11mm Proximity Probe(transducer)that senses shaft position.

BENTLY 330180-50-05:A Proximitor(sensor power supply and signal conditioner)that powers the probe and provides the raw signal to the monitor.

BENTLY 3500/25:A Keyphasor®Module,essential for providing the once-per-revolution timing pulse for phase measurement.

BENTLY 3500/15:A TMR(Triple Modular Redundant)Power Supply for the 3500 rack,ensuring ultra-high availability.

BENTLY 3500/92:A Communication Gateway module to interface the 3500 system with plant DCS or asset management software.

BENTLY 125792-01:A similar axial position monitoring module for thrust bearing protection,often used alongside radial vibration monitors.

BENTLY 3500/22M:A transient data interface module for capturing high-speed waveform data during startup or trips.

BENTLY System 1®Software:The advanced analytics platform that turns data from the 125680-01into actionable maintenance insights.

Installation,Maintenance,and Full-Cycle Support

Installation and Commissioning:Proper installation of the BENTLY 125680-01is a precision task.It begins with the correct mechanical installation and gap setting of the proximity probes on the machinery,which is critical for accurate measurement.The module is then installed in a designated slot in the 3500 series rack.Wiring from the proximitors must use shielded,twisted-pair cables,routed away from power lines to minimize noise.Commissioning involves configuring the module via dedicated software:setting measurement ranges(mils/µm),defining alarm setpoints(Alert,Danger),calibrating the 4-20mA outputs,and verifying the Keyphasor signal.A”bump test”or controlled machine run is typically performed to validate the entire measurement chain’s response.

Maintenance and Lifecycle Support:These modules are designed for long-term,stable operation.Routine maintenance involves verifying calibration during scheduled outages,checking cable and connector integrity,and monitoring system health indicators.The modular design allows for straightforward replacement if necessary.We provide comprehensive support for the BENTLY 125680-01throughout its service life.This includes supplying genuine,factory-certified new or refurbished modules,technical assistance for configuration and troubleshooting,and guidance on best practices for system health checks.Given the critical nature of machinery protection,we ensure the components we supply meet the original performance specifications to maintain the integrity of your safety system.Our expertise helps you maximize the diagnostic value of your investment while ensuring relentless protection for your most valuable rotating assets.Contact us for compatibility verification,system audits,and reliable spare parts supply.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!