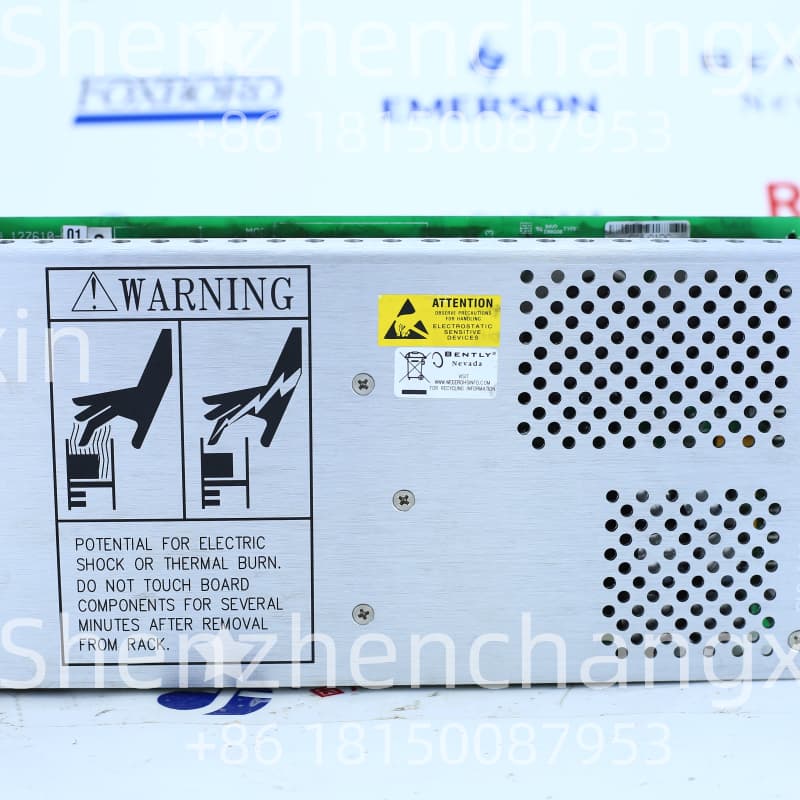

BENTLY 3500/05 OEM I/O Expansion Module for 3500 Machinery Monitoring Racks

Description

The BENTLY 3500/05 is a versatile digital input/output(I/O)interface module from Emerson’s Bently Nevada 3500 Machinery Protection System,designed to bridge discrete field signals—such as start/stop commands,valve positions,or external trip requests—with the internal logic of the 3500 rack.It provides 16 configurable channels that can be independently set as digital inputs or relay outputs,enabling seamless integration between the protection system and plant-wide control infrastructure like PLCs,DCS,or emergency shutdown panels.

Unlike dedicated monitor or relay modules,the 3500/05 acts as a programmable gateway,enhancing system flexibility without consuming additional rack slots for basic interlock functions.

Application Scenarios

At a natural gas processing facility in Alberta,operators needed to synchronize compressor startup sequences with lube oil pressure validation and isolation valve status—tasks previously handled by hardwired relays prone to drift and miswiring.By deploying the BENTLY 3500/05,engineers configured eight channels as inputs(reading oil pressure switches and valve limit switches)and eight as outputs(to enable motor starters and alarm horns).The 3500 system now validates all permissives before allowing rotation and triggers a coordinated shutdown if any condition fails.This reduced commissioning time by 60%and eliminated nuisance trips caused by contact bounce—showcasing how the BENTLY 3500/05 transforms rigid safety logic into intelligent,software-managed sequences.

Parameter

Main Parameters Value/Description

Product Model 3500/05

Manufacturer Bently Nevada(Emerson)

Product Category Programmable digital I/O interface module

Total Channels 16(user-configurable per channel)

Channel Types Digital Input(DI)or Relay Output(DO)–software-selectable

Digital Input Voltage 24 V DC nominal(18–30 V acceptable),sink/source capable

Relay Output Type Form A(SPST-NO)solid-state or electromechanical(configurable)

Relay Load Rating 2 A 30 V DC/1 A 120 V AC(resistive)

Response Time<5 ms for input detection;<10 ms for output activation

Electrical Isolation 500 V RMS channel-to-channel and to backplane

LED Indicators Per-channel status LEDs(green=active/high)

Mounting Single-slot(25 mm)in standard 3500 chassis(Slot 2–14)

Environmental Rating 0°C to+65°C;CE,CSA certified

Configuration Tool Bently Nevada 3500 Configuration Software(v5.0+)

Note:Channel configuration is stored in non-volatile memory—no reprogramming after power loss.

Technical Principles and Innovative Values

Innovation Point 1:Fully software-defined I/O—each of the 16 channels can be individually assigned as input or output during configuration,eliminating the need for multiple fixed-function modules.

Innovation Point 2:Direct integration with 3500 logic solvers(e.g.,3500/53)enables complex interlock sequences like“allow start only if vibration<2 mm/s AND lube pressure OK”—all within the safety-certified 3500 environment.

Innovation Point 3:Solid-state output option reduces wear in high-cycle applications(e.g.,alarm pulsing),while electromechanical relays support higher inrush currents for contactor coils.

Innovation Point 4:Front-access terminal blocks simplify field wiring and troubleshooting without removing the module from the rack—critical in live industrial environments.

Innovation Point 5:Real-time status reporting via the 3500 backplane allows DCS systems to monitor I/O health(e.g.,“Valve Open”feedback)alongside vibration data,creating a unified operational picture.

Application Cases and Industry Value

In a geothermal power plant in Iceland,steam turbine auxiliaries required precise coordination between condensate pump status,gland steam pressure,and turning gear engagement.Legacy relay panels were unreliable in the high-humidity environment.After replacing them with BENTLY 3500/05 modules integrated into the existing 3500 rack,the plant achieved deterministic control logic with full auditability.During a recent grid disturbance,the system correctly inhibited turbine roll-off because the turning gear was not engaged—a condition detected via a 3500/05 input—and prevented mechanical damage.Maintenance staff now use the module’s diagnostic logs to verify sequence integrity during monthly tests,significantly improving compliance with ISO 55000 asset management standards.

Related Product Combination Solutions

3500/15 133292-01:Communication module that exports 3500/05 I/O status to Modbus TCP/IP or Ethernet/IP

3500/53 133350-01:Voting/logic solver that uses 3500/05 inputs to trigger redundant trip decisions

3500/42M 140482-01:Vibration monitor whose alarms can drive 3500/05 outputs for local horn/strobe activation

3500/22-01-01-00:Temperature module that can interlock with 3500/05 to block startup on high bearing temp

3500 Chassis 133192-01:Standard 14-slot rack housing the 3500/05

Allen-Bradley 1756-EN2T:EtherNet/IP adapter for integrating 3500 I/O into ControlLogix via 3500/15

Honeywell Safety Manager:Can receive hardwired signals from 3500/05 relays for SIS-level shutdowns

3500 Keyphasor Module 125840-01:Provides speed reference to gate 3500/05 permissive logic during run-up

Together,these components enable a tightly integrated,code-compliant machinery control and protection ecosystem.

Installation,Maintenance,and Full-Cycle Support

The BENTLY 3500/05 installs in any non-power slot(2–14)of a 3500 rack.Wiring connects to removable front terminal blocks—color-coded for inputs(blue)and outputs(red)—enabling rapid field changes.During configuration,use the 3500 software to assign each channel,set debounce filters for noisy inputs,and define fail-safe states(e.g.,outputs de-energize on module fault).

In service,the module requires no calibration.Its diagnostic LEDs provide immediate visual feedback for troubleshooting.If replacement is needed,hot-swap capability minimizes downtime.

We maintain genuine BENTLY 3500/05 inventory sourced through authorized Emerson channels.Each unit undergoes functional validation:input response test,output load test,and software recognition check.We provide 12-month warranty,detailed test reports,and multilingual engineering support for logic design,integration,and compliance documentation.

Contact us for a customized solution to unlock flexible,reliable,and auditable discrete I/O within your Bently Nevada 3500 protection architecture.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!