ELAU MC-4/11/01/400 in Automation Applications

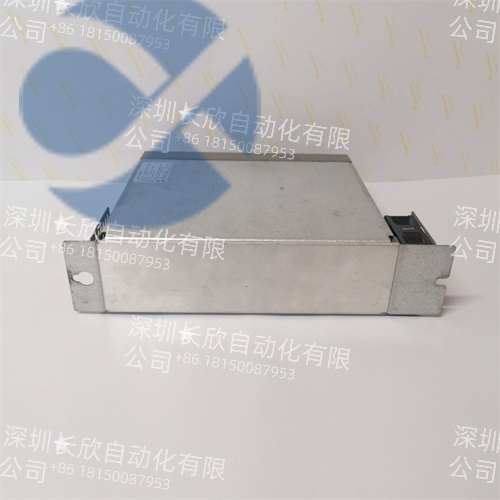

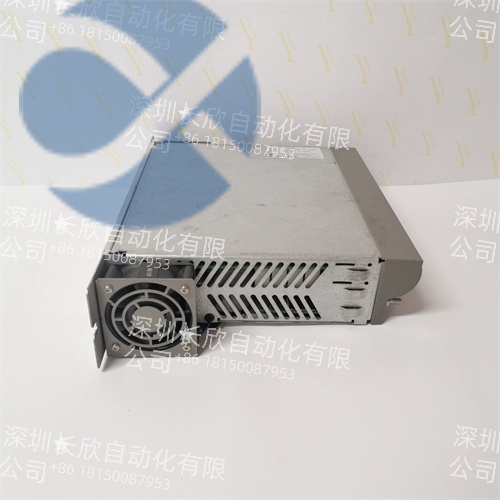

Product Overview

The ELAU MC-4/11/01/400represents ELAU’s advanced modular servo drive designed for high-performance motion control applications in packaging,converting,and manufacturing automation.This sophisticated drive module forms part of ELAU’s integrated automation system,providing precise control for servo motors in demanding industrial applications.The MC-4/11/01/400combines powerful processing capabilities with flexible connectivity options,enabling complex motion profiles and synchronization tasks essential for today’s high-speed production equipment.

Engineered with precision motion control as its core focus,the ELAU MC-4/11/01/400delivers exceptional dynamic performance through advanced control algorithms and high-speed processing architecture.The drive’s modular design allows seamless integration into ELAU’s automation platform,supporting distributed control architectures that reduce wiring complexity and improve system scalability.In high-speed packaging machinery applications,the MC-4/11/01/400has demonstrated remarkable reliability,achieving positioning accuracy within±1 encoder count while maintaining smooth operation at speeds exceeding 5,000 RPM,making it ideal for applications requiring both speed and precision.

Application Scenarios

In a pharmaceutical blister packaging line modernization project,the ELAU MC-4/11/01/400servo drives were implemented to control 12 axes of motion including web handling,sealing,and cutting operations.The drives’electronic gearing functionality enabled perfect synchronization between the film feed and product insertion mechanisms,reducing material waste by 23%compared to the previous mechanical system.The MC-4/11/01/400units demonstrated exceptional stability during rapid acceleration/deceleration cycles,maintaining positional accuracy within 10 microns throughout production runs.The built-in safety torque off(STO)functionality provided Category 3 safety performance,allowing the machinery to meet the latest safety standards without additional hardware.The production manager reported:”The MC-4/11/01/400drives have provided unprecedented control accuracy,enabling us to increase line speed by 18%while improving product quality consistency.”

Technical Specifications

Product Model:MC-4/11/01/400

Manufacturer:ELAU(now part of Schneider Electric)

Product Type:Digital Servo Drive

Output Current:11A RMS continuous,33A peak

Supply Voltage:400V AC three-phase

Power Rating:4kW

Communication Interface:SERCOS III,Ethernet

Feedback Resolution:24-bit absolute encoder support

Control Modes:Torque,Velocity,Position,Electronic Gearing

Switching Frequency:4kHz/8kHz/16kHz selectable

Dynamic Response:2.5kHz velocity loop bandwidth

Safety Functions:STO(Safe Torque Off)

Operating Temperature:0°C to+55°C

Storage Temperature:-25°C to+85°C

Protection Class:IP20

Mounting:DIN rail or panel mount

Certifications:CE,UL,cULus

Technical Principles and Innovation Values

The ELAU MC-4/11/01/400utilizes advanced field-oriented control(FOC)technology with automatic motor parameter identification,ensuring optimal performance with a wide range of servo motors.The drive’s adaptive tuning capability continuously optimizes control parameters based on load conditions,maintaining consistent performance despite varying inertial loads.The high-resolution feedback processing(24-bit)provides exceptional position resolution,enabling precise control even at very low speeds.

Innovation Point 1:The integrated SERCOS III real-time Ethernet interface provides deterministic communication with cycle times as low as 31.25 microseconds,enabling precise multi-axis synchronization.The dual-port switch architecture allows daisy-chained network topologies that reduce wiring and improve reliability.

Innovation Point 2:Advanced vibration suppression algorithms actively detect and compensate for mechanical resonance,allowing higher servo gains without instability.This feature is particularly valuable in systems with long mechanical transmissions or compliant couplings where resonance typically limits performance.

Innovation Point 3:The drive’s modular safety concept incorporates Safe Torque Off(STO)functionality that meets SIL 3/PL e requirements,providing safety without external relays.The safety functions are integrated directly into the drive architecture,reducing component count and simplifying safety system validation.

Application Cases and Industry Value

In a corrugated box manufacturing plant,the ELAU MC-4/11/01/400drives were deployed to upgrade a flexo folder-gluer machine’s critical axes.The drives’electronic cam functionality replaced mechanical cams,allowing quick changeovers between different box sizes.The MC-4/11/01/400units maintained perfect synchronization between the printing cylinders and cutting sections,reducing setup time from 45 minutes to under 5 minutes.The plant engineer noted:”The MC-4/11/01/400drives have revolutionized our changeover process.The ability to store hundreds of recipes and recall them instantly has increased our equipment utilization by 30%.The maintenance savings from eliminating mechanical wear parts have exceeded$15,000 annually.”

Related Product Combination Solutions

The MC-4/11/01/400integrates seamlessly with ELAU’s automation ecosystem:

PacDriveautomation controllers for centralized control

SMARTERservo motors for optimized performance matching

Cseries I/O modules for distributed peripheral control

Safetymodules for expanded safety functionality

HMI panels for operator interface

Automation Studio software for unified programming environment

Installation,Maintenance and Full-Cycle Support

Installation requires proper grounding and EMC practices,with adequate clearance for ventilation.Motor cables should use shielded twisted-pair types with proper grounding at both ends.The drive parameters should be configured using ELAU’s Automation Studio software,with automatic motor identification performed during commissioning.

Routine maintenance includes periodic inspection of connections and cooling surfaces.The drive’s diagnostic functions monitor operating conditions and provide early warning of potential issues.Firmware updates are available to enhance functionality and maintain compatibility.

Contact us today for customized motion solutions using genuine ELAU MC-4/11/01/400servo drives.Our technical team provides system design support and configuration assistance.

We guarantee genuine ELAU MC-4/11/01/400servo drives with full functionality testing.Our engineering support ensures optimal system performance and long-term reliability.

Bently Nevada | General Electric | Vibration Motors | ABB | Honeywell | Emerson | B&R | Yokogawa | Woodward | Schneider