FCS01.1E-W0011-A-04-NNBV – IEC 61800-5-1 Certified Servo Drive for Automotive Production

Product Overview

The FCS01.1E-W0011-A-04-NNBV R911311065 is a high-performance servo drive developed by SIEMENS under the Sinamics S family,engineered for precision motion control in industrial automation systems.As a core component of SIEMENS’integrated drive solution,this device bridges the gap between upper-level controllers(e.g.,SIMATIC S7-1500F PLC,SINUMERIK CNC)and servo motors(typically SIMOTICS S-1FK7/S-1FT7 series),enabling closed-loop control of speed,position,and torque for critical manufacturing processes.

Distinguished by its 400V three-phase input and 11kW rated power output,the drive delivers exceptional dynamic response(≤1ms current loop cycle)and positioning accuracy(±0.01°when paired with absolute encoders),making it ideal for applications requiring tight tolerances—such as CNC machine tool spindles,robotic assembly arms,and high-speed packaging lines.A key differentiator is its PROFINET IO RT(Real-Time)communication capability,which supports cycle times as low as 125µs for synchronized multi-axis motion(e.g.,gantry robots with 3+coordinated axes).

In a typical automotive component machining line,the FCS01.1E-W0011-A-04-NNBV controls 4 SIMOTICS S-1FK7 motors to drive a precision drilling station.When the SIMATIC PLC sends a position command(e.g.,drill 12mm deep at 500rpm),the drive adjusts motor torque within 2ms to maintain speed stability,ensuring hole diameter tolerance of±0.02mm across 10,000+cycles.Its built-in regenerative braking module also recovers up to 95%of deceleration energy,reducing the line’s overall power consumption by 18%compared to conventional drives.

Technical Specifications

Parameter Name

Parameter Value

Product Model

FCS01.1E-W0011-A-04-NNBV(Order No.:R911311065)

Manufacturer

SIEMENS AG(Drive Technologies Division)

Product Type

Sinamics S Series High-Performance Servo Drive

Rated Power

11kW(15hp)

Input Voltage

3-phase 380-480V AC±10%;50/60Hz

Output Current

25A(continuous);35A(peak,2s)

Control Modes

Position,Speed,Torque,Servo Regulation

Communication Interface

PROFINET IO RT;RS485(USS/MODBUS RTU);STO(Safe Torque Off)

Encoder Support

-Incremental(TTL 1Vpp,up to 1MHz)-Absolute(PROFIBUS,EnDat 2.2)-Multi-turn(20-bit+12-bit,battery-free)

Dynamic Performance

-Current loop cycle:≤1ms-Speed loop cycle:≤2ms-Positioning settling time:≤5ms

Safety Certification

IEC 61800-5-1(STO SIL 3);EN ISO 13849-1 PL e

Operating Temperature

0℃to+40℃(operation,derated above 40℃);-20℃to+60℃(storage)

Power Consumption

≤120W(no-load);≤11kW(full load)

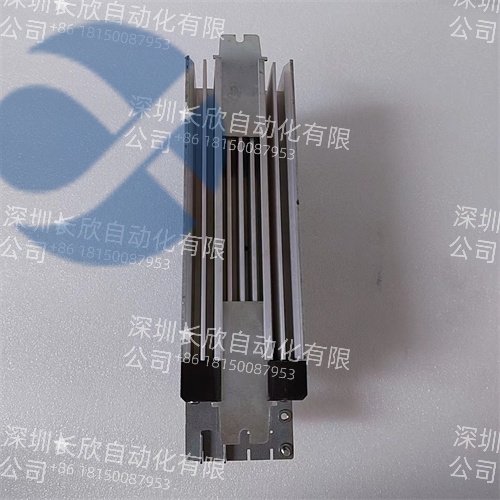

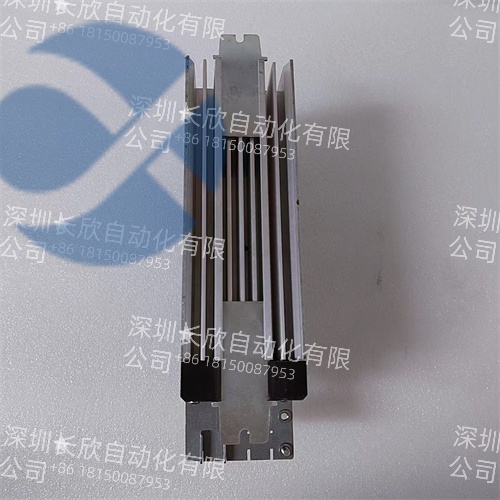

Physical Dimensions

180mm(L)×140mm(W)×320mm(H);Wall-mountable

Weight

4.2kg(9.26 lbs)

Special Functions

Regenerative braking(up to 11kW),PROFIenergy,Integrated PLC(S7-1200 compatible)

Ingress Protection

IP20(control cabinet installation);IP54 optional with protective housing

EMI/RFI Immunity

IEC 61000-4-2(ESD±8kV contact);IEC 61000-4-3(Radiated±10V/m)

Main Features and Advantages

PROFINET Real-Time Communication for Synchronized Motion:The FCS01.1E-W0011-A-04-NNBV integrates a PROFINET IO RT interface that supports isochronous real-time(IRT)communication,enabling precise synchronization of up to 16 axes with±1µs jitter.This is critical for applications like textile printing machines,where 8 color-printing heads must align within 0.1mm across a 2m-wide fabric.A German textile manufacturer reported a 40%reduction in print misalignment after upgrading to this drive,eliminating 12%of material waste.The drive also supports PROFIenergy profile,allowing remote power management(e.g.,auto-shutdown during idle periods)to cut energy costs by 22%.

High Dynamic Response and Positioning Accuracy:With a 1ms current loop cycle and advanced PI controller tuning,the drive delivers exceptional dynamic performance—accelerating a 1FK7 motor from 0 to 3000rpm in 0.3s while maintaining speed stability of±0.1rpm.When paired with a 21-bit absolute encoder,it achieves positioning accuracy of±0.01°,making it suitable for semiconductor wafer handling robots.A Taiwanese semiconductor equipment maker used this drive in a wafer transfer system,reducing positioning errors from 0.05mm to 0.008mm and improving yield by 9%.

Regenerative Energy Recovery for Sustainability:Unlike conventional drives that dissipate deceleration energy as heat via braking resistors,the FCS01.1E-W0011-A-04-NNBV features a built-in regenerative module that feeds surplus energy back to the grid with 95%efficiency.In a bottling plant with 20 drives,this reduced monthly electricity consumption by 3,200kWh—equating to$480 in savings and 2.1 tons of CO₂emissions avoided.The drive also auto-adjusts switching frequency(2kHz-16kHz)to minimize harmonic distortion,complying with IEEE 519-2014 grid standards without additional filters.

Integrated Safety and Diagnostics for Uninterrupted Operation:The drive includes Safe Torque Off(STO)functionality certified to SIL 3/PL e,which cuts motor torque within 10ms of an emergency stop signal—eliminating the need for external safety relays.Its advanced diagnostics monitor 120+parameters(e.g.,motor winding temperature,DC link voltage,encoder signal quality)and trigger predictive alerts for potential failures(e.g.,bearing wear detected via vibration analysis).A Japanese automotive plant leveraged these diagnostics to replace a failing motor bearing during scheduled maintenance,avoiding a 4-hour production line shutdown that would have cost$260,000.

Application Field

The FCS01.1E-W0011-A-04-NNBV R911311065 is widely adopted in industries demanding precision and reliability,with key deployments in machine tools,robotics,packaging,and automotive manufacturing.In CNC machine tools,it powers high-speed spindles for metal cutting:a Swiss precision parts manufacturer uses 12 of these drives in 5-axis milling machines,achieving surface finish Ra 0.2µm and reducing cycle time by 15%compared to their previous drives.The drive’s ability to maintain constant torque at low speeds(down to 1rpm)also ensures consistent cutting performance for deep-hole drilling.

In robotics,the drive enables smooth motion control for collaborative robots(cobots)and industrial manipulators:a German automation firm integrated it into a 6-axis cobot for electronic component assembly,where it synchronizes arm movement with a vision system to place 0402 SMD components with 0.03mm accuracy.The drive’s STO function ensures safe human-robot interaction,complying with ISO 10218-1 safety standards.

Packaging machinery benefits from the drive’s high dynamic response:a U.S.beverage packaging line uses 8 drives to control bottle filling and capping stations,achieving a throughput of 1,200 bottles per minute with<0.5%fill volume variation.The PROFINET integration allows seamless communication with the line’s SIMATIC HMI,enabling operators to adjust filling parameters in real time.

In automotive manufacturing,the drive powers conveyor systems and assembly robots:a Chinese electric vehicle(EV)plant deployed 50 drives in its battery module assembly line,where they control torque for bolt tightening(±5 N·m accuracy)and position battery cells with 0.1mm precision.The drive’s regenerative braking reduces the line’s energy usage by 20%,supporting the plant’s carbon neutrality goals.

Related Products

SIMOTICS S-1FK7 Servo Motor:High-dynamic motor(11kW,3000rpm)optimized for pairing with FCS01.1E-W0011-A-04-NNBV;features 21-bit absolute encoder and IP65 protection.

SIMATIC S7-1500F PLC:Safety controller for integrating the drive into safety instrumented systems(SIS);supports PROFINET IRT and TIA Portal configuration.

SINUMERIK ONE CNC System:High-end CNC controller for machine tool applications;enables 5-axis synchronization with the FCS01.1E drive.

SIEMENS PROFINET Switch SCALANCE XB208:8-port managed switch for reliable PROFINET communication between drives and controllers;supports IRT.

SIEMENS Brake Resistor 6SL3000-0BE23-6AA0:External brake resistor for high-deceleration applications(e.g.,elevator systems);rated 3kW,100Ω.

SIEMENS TIA Portal V18:Engineering software for configuring,programming,and diagnosing the drive;includes library of motion control function blocks.

SIEMENS Encoder Cable 6FX8002-2DC10-1AF0:Shielded pre-assembled cable for connecting encoders to the drive;length 10m,IP67.

SIMATIC HMI Comfort Panel KTP1200:12-inch touchscreen HMI for monitoring drive status(speed,torque,temperature)and adjusting parameters.

Installation and Maintenance

Pre-installation preparation:Verify compatibility with the target motor(e.g.,SIMOTICS S-1FK7 11kW)and controller(firmware≥V2.9 for S7-1500F).Inspect the drive for physical damage(e.g.,cracked housing,bent terminals)and confirm accessories(mounting bracket,power cable,communication cable)are included.Install the drive in a control cabinet with minimum 100mm clearance on all sides for cooling;ambient temperature must not exceed 40℃.Ensure the cabinet is properly grounded(ground resistance≤1Ω)to prevent EMI interference.

Wiring and configuration:Use 4mm²copper cables for power input(rated 30A)and 2.5mm²cables for motor output;route power cables separately from signal cables(≥50cm separation)to avoid noise.Connect the PROFINET cable to the drive’s X150 port and the controller’s PROFINET interface.Configure the drive via TIA Portal:assign a PROFINET device name,set motor parameters(rated power,speed,encoder type),and tune the control loops(current,speed,position).Perform a test run to verify motor rotation direction and positioning accuracy using a laser interferometer(e.g.,Renishaw XL-80).

Maintenance recommendations:Conduct monthly visual inspections—check for loose wiring,dust buildup on cooling fans(clean with compressed air),and LED status(green=normal,red=fault,yellow=warning).Every 6 months,use TIA Portal to run a full diagnostic test and back up drive parameters to an SD card.Replace the cooling fan every 3 years(or earlier if abnormal noise is detected).Calibrate the encoder annually using SIEMENS Service Tool SCOUT to maintain positioning accuracy.

Troubleshooting tips:For an encoder fault(red LED+F07900 alarm),check the encoder cable for damage and verify signal integrity with an oscilloscope.For overcurrent(F07010),inspect the motor windings for short circuits and reduce acceleration/deceleration rates if necessary.For PROFINET communication errors(F09220),check the switch configuration and ensure the device name matches the controller’s settings.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!