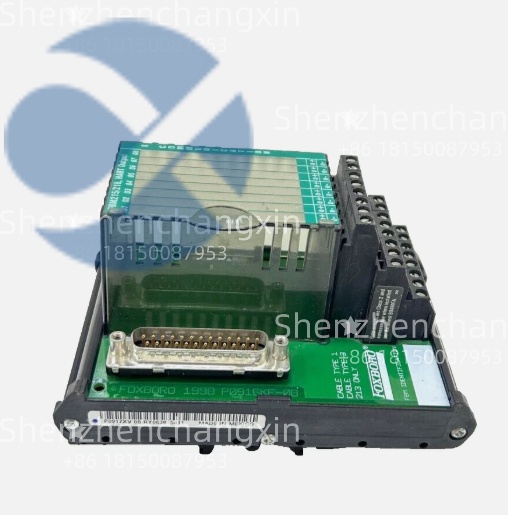

FBM211 Fieldbus Module | High-Density Isolated Digital Input Card

Description

The FOXBORO FBM211(also cataloged as P0911H)is an 8-channel,24VDC digital input fieldbus module for the FOXBORO I/A Series distributed control system.This industrial-grade module serves as a critical interface,converting field device contact statuses(ON/OFF)into digital data for the control system.It provides reliable monitoring of discrete devices like limit switches,pushbuttons,relays,and proximity sensors with robust signal conditioning and isolation for demanding process applications.

Application Scenarios

In a pharmaceutical batch processing facility,precise sequence control is critical.A reactor cleaning system uses multiple proximity sensors to verify valve positions and a series of flow switches to confirm line clearance.Historically,intermittent false signals from these sensors—caused by electrical noise from motor starters—would cause the automated cleaning cycle to abort,requiring manual intervention and delaying production.The control engineer replaced aging remote I/O cards with FOXBORO FBM211modules in the field enclosures.The FBM211’s high noise immunity and configurable filtering eliminated the false triggers.Furthermore,its per-channel status LEDs allowed technicians to visually confirm which sensor was active during commissioning and troubleshooting,cutting debug time by 70%.The module’s robust performance in the humid wash-down area ensured reliability,and its hot-swap capability allowed a failed unit to be replaced during a brief planned maintenance window without a full system shutdown,maximizing production uptime.

Parameter

Here are the key technical specifications for the FOXBORO FBM211module:

Main Parameters

Value/Description

Product Model

FBM211(P0911H)

Manufacturer

Foxboro(Emerson Process Management)

Product Category

Digital Input Fieldbus Module(FBM)

System Compatibility

Foxboro I/A Series DCS

Number of Channels

8 isolated channels

Input Type

24 VDC,Sinking(NPN)or Sourcing(PNP)-software selectable

Input Voltage Range

0 to 30 VDC continuous

“ON”Signal Level

15 to 30 VDC

“OFF”Signal Level

0 to 5 VDC

Input Current

Typically 7 mA per point at 24 VDC

Response Time

<5 milliseconds(ensures fast detection for interlocking)

Isolation

500 VAC channel-to-channel and channel-to-fieldbus

Connection

Removable screw terminal block

Status Indication

Per-channel green LED(ON=field device active)

Power Consumption

Derived from the FBM fieldbus

Operating Temperature

-40°C to 70°C(-40°F to 158°F)

Technical Principles and Innovative Values

The FOXBORO FBM211excels through its intelligent design focused on reliability,flexibility,and seamless system integration within the I/A Series architecture.

Innovation Point 1:Universal Input Configuration via Software

A standout feature is its software-configurable input type.Each of the eight channels can be independently set as either a sinking(NPN)or sourcing(PNP)input through the I/A Series configuration software.This is achieved via solid-state switching circuitry that reconfigures the current path.This eliminates the need for physical jumpers,hardware modifications,or stocking separate module variants,providing unmatched flexibility for plants with mixed field device standards and slashing spare parts inventory requirements.

Innovation Point 2:Advanced Signal Integrity and Diagnostics

The module incorporates multi-stage filtering and high-threshold detection to reject electrical noise,contact bounce,and voltage transients common in industrial environments.This ensures that a valid ON/OFF signal is cleanly and reliably presented to the controller,which is fundamental for stable logic execution.Enhanced diagnostics are communicated to the control system,allowing for predictive maintenance by identifying trends like a decaying field power source or a failing sensor before it causes a process fault.

Innovation Point 3:True Hot-Swap Capability in Redundant Systems

Engineered for high availability,the FBM211supports true hot-swap replacement in systems configured with redundant fieldbus modules.A faulty module can be removed and replaced without de-energizing the associated field devices or interrupting the control process.The controller automatically recognizes the new module and downloads its configuration,minimizing process disruption and mean time to repair(MTTR)—a critical feature for continuous process industries.

Innovation Point 4:Ruggedized Industrial Design for Extended Life

Built to withstand harsh conditions,the module operates across an extreme temperature range.Its components are selected and tested for long-term reliability,and the design minimizes heat generation.This durability ensures stable operation in non-climatized field enclosures close to process equipment,reducing signal degradation over long wire runs and improving overall system accuracy.

选择深圳长欣,享受无忧的售后服务和高品质产品。