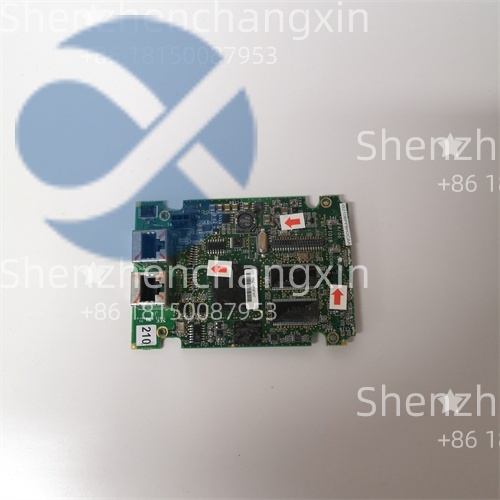

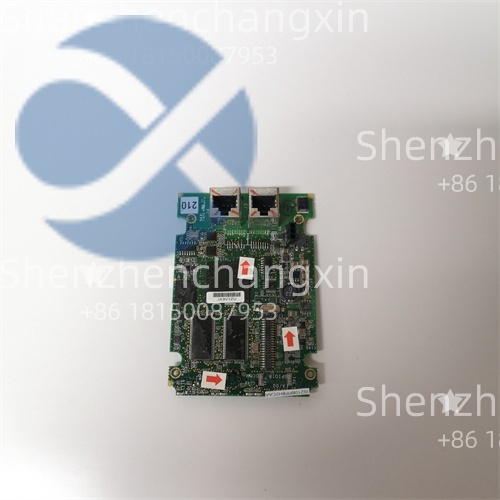

GE IS210WSVOH1AE Servo Controller Module for Mark VIe Turbine Control Systems

Description

The GE IS210WSVOH1AE is a high-performance servo output module engineered by General Electric for its Mark VIe turbine control platform.As a core component of the Speedtronic™system,it delivers precise,closed-loop electro-hydraulic control to critical actuators such as fuel valves,inlet guide vanes,and steam stop valves.The GE IS210WSVOH1AE integrates command generation,LVDT feedback processing,and fault diagnostics into a single ruggedized board—ensuring millisecond-level response for both normal regulation and emergency trip sequences in gas,steam,and combined-cycle power plants.

Application Scenarios

During a repowering project at a Midwest peaker plant,engineers replaced aging Mark V controls with the modern Mark VIe system but faced instability in fuel valve positioning during rapid load changes.The root cause?Inadequate servo resolution and slow LVDT sampling in legacy hardware.After installing the GE IS210WSVOH1AE,the system achieved±0.1%position accuracy thanks to its 16-bit DACs and 1 kHz feedback loop.More critically,during a simulated grid fault,the GE IS210WSVOH1AE triggered a full fuel cutoff in under 80 ms—well within API 612 safety margins.Plant operators now report smoother ramp rates and zero spurious trips over 18 months of operation.This transformation underscores how the GE IS210WSVOH1AE turns actuator control from a mechanical bottleneck into a digital precision asset.

Parameter

Main Parameters Value/Description

Product Model GE IS210WSVOH1AE

Manufacturer General Electric(GE Power/Baker Hughes)

Product Category Servo Output I/O Module for Mark VIe Turbine Control System

Channels 4 independent servo output channels

Output Type±10 VDC command signal to servo valves

Feedback Input Dual LVDT(Linear Variable Differential Transformer)per channel

Sampling Rate Up to 1 kHz per channel

Resolution 16-bit digital-to-analog conversion

Redundancy Support Full TMR(Triple Modular Redundant)compatibility in Mark VIe architecture

Diagnostic Features Open-circuit/short-circuit detection,LVDT health monitoring,output current sense

Power Supply+5 VDC,±15 VDC(from Mark VIe I/O terminal board)

Operating Temperature 0°C to+60°C

Mounting Plugs into IS200/IS210 series terminal boards(e.g.,IS210VTUH1A)in Mark VIe rack

Certifications CE,UL,CSA,API 670,IEC 61508(SIL2 capable)

Technical Principles and Innovative Values

Innovation Point 1:Integrated Closed-Loop Control per Channel

Unlike generic analog output cards,the GE IS210WSVOH1AE runs independent PID loops for each actuator,continuously comparing LVDT feedback against turbine controller setpoints—eliminating external loop controllers and reducing latency.

Innovation Point 2:Fail-Safe Trip Logic Embedded in Hardware

The GE IS210WSVOH1AE includes hardwired trip paths that bypass software during emergencies,ensuring valve closure even if the main processor fails—critical for compliance with API 612 and NFPA 85.

Innovation Point 3:Self-Calibrating LVDT Interface

The module auto-detects LVDT excitation frequency and phase,then compensates for cable resistance and temperature drift—maintaining accuracy without manual null adjustments.

Innovation Point 4:Real-Time Health Scoring

Using built-in current and voltage sensors,the GE IS210WSVOH1AE calculates“actuator health indices”(e.g.,stiction,hysteresis)and reports them via the Mark VIe network—enabling predictive maintenance before failures occur.

Application Cases and Industry Value

At a European combined-cycle plant running two 9FB gas turbines,recurring IGV(Inlet Guide Vane)oscillations caused combustion instability alarms.Analysis revealed degraded LVDT linearity in the old servo cards.After upgrading to the GE IS210WSVOH1AE,the enhanced feedback resolution stabilized vane positioning across all load ranges.Over the next year,NOx emissions variability dropped by 22%,and hot gas path inspections showed reduced thermal fatigue—extending blade life by an estimated 15,000 hours.Maintenance staff also leveraged the module’s diagnostic logs to schedule a valve rebuild during a planned outage,avoiding an unscheduled$500K forced downtime.The GE IS210WSVOH1AE thus delivered not just control—but longevity and compliance.

Related Product Combination Solutions

GE IS210VTUH1A:Terminal board that hosts the GE IS210WSVOH1AE and provides field wiring interfaces.

GE IS220PDIOH1A:Discrete I/O module—often used alongside GE IS210WSVOH1AE for valve limit switch feedback.

GE IC698CRE030:Mark VIe controller CPU—generates servo setpoints consumed by the GE IS210WSVOH1AE.

GE IS210SVAOH1A:Alternative servo module for non-LVDT actuators—complements GE IS210WSVOH1AE in mixed systems.

BENTLY 3500/42:Vibration monitor—data often correlated with GE IS210WSVOH1AE actuator behavior for root-cause analysis.

ABB AC 800PEC:Third-party turbine controller—can interface with GE IS210WSVOH1AE via custom terminal adaptations in hybrid retrofits.

HIMA H51q:Safety PLC—receives trip signals derived from GE IS210WSVOH1AE diagnostics in SIL2 shutdown systems.

GE IS200SSV0H1A:Legacy Mark VI servo card—GE IS210WSVOH1AE is its direct Mark VIe successor with enhanced diagnostics and redundancy.

Installation,Maintenance,and Full-Cycle Support

The GE IS210WSVOH1AE installs directly onto a compatible terminal board(e.g.,IS210VTUH1A)within a Mark VIe I/O chassis.No jumpers or calibration pots are required—configuration is handled entirely through ToolboxST™software,where engineers define LVDT scaling,loop gains,and alarm thresholds.The module supports online replacement in redundant systems,minimizing turbine downtime.

Routine maintenance involves reviewing diagnostic trends in ToolboxST for signs of increasing drive current or LVDT noise—early indicators of mechanical wear.In the event of failure,the unit can be swapped in under 10 minutes,with automatic parameter reload from the controller.Our company maintains a ready inventory of factory-tested GE IS210WSVOH1AE modules,each verified for output accuracy,LVDT response,and trip functionality on live Mark VIe test benches.We offer 12-month warranty,pinout documentation,and remote support for commissioning and troubleshooting.

Contact us for a customized solution—whether you’re commissioning a new turbine,modernizing legacy controls,or securing spare parts for your Mark VIe system,the GE IS210WSVOH1AE ensures your critical actuators respond with precision,speed,and unwavering reliability.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!