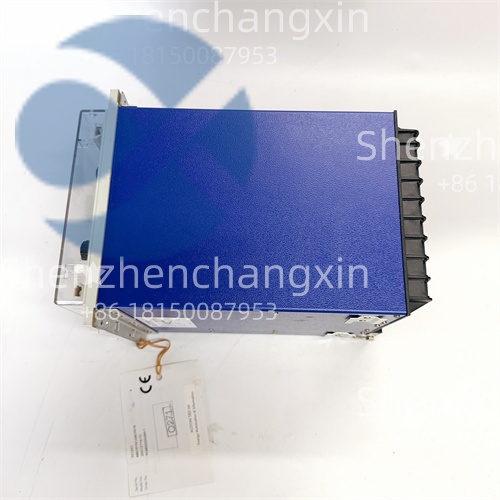

Rugged MBCI01N1AB0761B with opto-isolated discrete channels

Product Overview

The ALSTOM MBCI01N1AB0761B is a high-reliability digital I/O communication interface module developed as part of Alstom Power Automation’s modular control architecture for turbine,generator,and excitation systems—widely deployed in thermal,hydroelectric,and nuclear power plants from the late 1990s through the early 2000s.Functioning as a bridge between field-level discrete signals(e.g.,breaker status,limit switches,trip contacts)and the central processing unit in Alstom’s Automatic Generator Control(AGC)or UNITROL®platforms,the MBCI01N1AB0761B enables deterministic acquisition and distribution of binary data across the system backplane.

Unlike standard I/O modules,the MBCI01N1AB0761B often serves as a carrier interface or bus coupler,managing communication between multiple plug-in I/O cards(such as MVDO or MVDI series)and the main controller via a proprietary parallel or serial backplane protocol.It typically mounts on a DIN rail within an I/O chassis and connects to a master CPU(e.g.,in an AGC-3000 rack)through a shielded multi-conductor ribbon cable or edge connector.Each channel features opto-isolation(typically 2.5 kV RMS)to protect the control logic from ground loops,voltage spikes,and electromagnetic interference common in high-energy environments.Although now a legacy product under GE Grid Solutions’support umbrella following Alstom’s automation division acquisition,the MBCI01N1AB0761B remains in active service globally due to its rugged design,long lifecycle,and seamless compatibility with existing Alstom control cabinets.

Technical Specifications

Parameter Name Parameter Value

Product Model MBCI01N1AB0761B

Manufacturer ALSTOM(legacy;support now under GE Grid Solutions)

Product Type Digital I/O Bus Interface/Carrier Communication Module

Function Backplane communication adapter for discrete I/O modules

Isolation 2.5 kV RMS(channel-to-bus and channel-to-channel)

Input/Output Type Digital(discrete),typically 24 VDC or contact sensing

Number of Channels Varies by system configuration(often supports 16–32 channels via daughter cards)

Communication Interface Proprietary Alstom I/O bus(parallel or serial,e.g.,via flat cable to CPU)

Power Supply+5 VDC and±15 VDC from backplane or external source

Operating Temperature 0°C to+60°C

Mounting DIN rail or chassis-mounted within I/O rack

Certifications Compliant with IEC 60633,IEEE 472(surge immunity)

Main Features and Advantages

Robust backplane integration for modular I/O expansion:The MBCI01N1AB0761B acts as a central hub that aggregates signals from multiple plug-in digital I/O modules,reducing wiring complexity and enabling scalable I/O density in compact control panels—ideal for retrofit projects with space constraints.

High noise immunity for safety-critical applications:With reinforced opto-isolation and conformal-coated PCBs,the module withstands fast transients,ESD,and ground potential rise near switchyards or excitation systems.This makes it suitable for use in generator protection,turbine trip logic,and synchronizing check circuits where signal corruption could lead to catastrophic failure.

Seamless compatibility with Alstom legacy ecosystems:Designed specifically for AGC-3000,UNITROL 1000/6000,and related platforms,the MBCI01N1AB0761B requires no firmware adaptation or gateway hardware.Its timing,addressing,and fault-reporting behavior are fully aligned with original system specifications,ensuring drop-in replacement during maintenance.

Diagnostic visibility and serviceability:Status LEDs indicate power,communication activity,and fault conditions per channel or module group.Combined with Alstom’s diagnostic software(e.g.,AGC Configurator),operators can quickly identify open circuits,shorted inputs,or communication timeouts—reducing mean time to repair(MTTR).

Long-term support through certified refurbishment:Despite discontinuation,the MBCI01N1AB0761B is available from authorized service providers who perform full functional testing,component-level repair(e.g.,replacing aging optocouplers),and recalibration.Units are delivered with traceable test reports,supporting compliance in regulated industries.

Application Field

The ALSTOM MBCI01N1AB0761B is predominantly used in utility-scale power generation control systems where reliable discrete signal handling is essential for operational safety and grid compliance.In hydroelectric stations,it interfaces with wicket gate limit switches,bearing temperature alarms,and circuit breaker auxiliary contacts to feed real-time status into turbine governor logic.In coal-and gas-fired plants,the module acquires boiler flame scanner signals,condenser vacuum switches,and generator differential relay outputs for inclusion in unit sequencing and protection schemes.

Nuclear facilities employ the MBCI01N1AB0761B in non-safety-related but vital auxiliary systems—such as diesel generator start-permissive logic or station blackout response panels—where its isolation meets IEEE 384 separation guidelines.Industrial cogeneration plants in oil&gas,mining,and chemicals rely on it for black-start interlocks and island-mode synchronization checks.Across Europe,Asia,and North America,transmission operators retain this module during partial DCS modernizations because of its proven interoperability with legacy relays,RTUs,and hardwired safety circuits.Even in hybrid renewable installations using synchronous condensers,the MBCI01N1AB0761B preserves investment in existing sensor infrastructure while integrating with upgraded control layers.

Related Products

MBCI01N1AB0761A:Earlier revision with minor firmware differences

MVDO21/MVDI11:Plug-in digital output/input modules used with MBCI01N1AB0761B

STO0982E01:Standard I/O carrier chassis compatible with this interface

AGC-3000:Alstom Automatic Generator Control system hosting the module

UNITROL 6000:Excitation platform commonly integrated with this I/O architecture

GE IC695MDL754:Modern PACSystems digital I/O module for migration paths

MVAW11B1AB9007A:Analog output counterpart in same ecosystem

AL132:Analog input module often used in parallel systems

Installation and Maintenance

Pre-installation:Confirm compatibility with the target I/O chassis and CPU model.Verify that the backplane or ribbon cable provides stable+5 VDC and correct signaling levels.Ensure field wiring uses shielded cables with single-point grounding to avoid noise coupling.Load appropriate configuration files in the host AGC engineering tool before powering up.

Maintenance:During outages,inspect for signs of optocoupler degradation(e.g.,slow response or leakage current)in units older than 15 years.Clean dust from ventilation slots on the I/O rack to prevent overheating.Validate channel functionality using a digital multimeter or automated test jig.Store spare MBCI01N1AB0761B modules in anti-static containers with desiccant;power them every 12–18 months to preserve component health.For critical applications,maintain a stock of refurbished units with recent validation certificates.

Product Guarantee

Originally manufactured under ISO 9001-certified processes,the ALSTOM MBCI01N1AB0761B was engineered for 20+years of continuous operation in industrial environments.While no longer in production,certified refurbishers provide tested replacements that undergo full electrical validation,thermal stress testing,and EMI resilience checks.Each unit includes a calibration/test report traceable to international standards and carries a standard 12-month warranty covering defects in materials and workmanship.This enduring support ensures that power generators can maintain regulatory compliance,operational continuity,and asset reliability—solidifying the MBCI01N1AB0761B’s role as a cornerstone of legacy control infrastructure well into the 2030s.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!