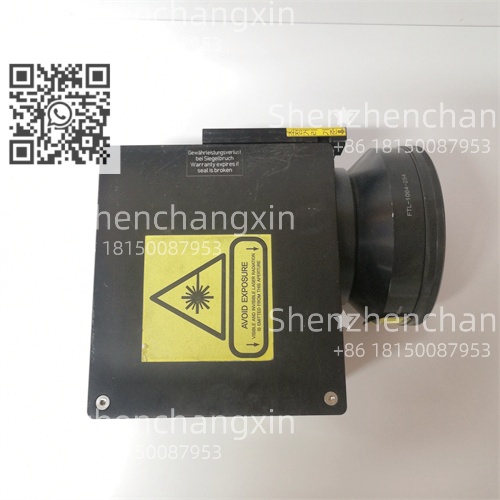

INTELLISCANDE14-1064NM – IP66 Protection, Automotive Part Marking, SCANLAB Genuine

Description

The SCANLAB SCANde INTELLISCANDE14-1064NM is a high-performance laser scanning galvo system engineered exclusively by SCANLAB,the global leader in laser scanning technology,serving as the”optical brain”for 1064nm wavelength laser systems.It specializes in precise,real-time deflection of laser beams via computer-controlled X/Y scanning mirrors,enabling ultra-accurate positioning of the laser focus on target surfaces—critical for applications demanding micron-level precision and high processing speeds.

Unlike generic galvo scanners that sacrifice stability for speed or vice versa,the INTELLISCANDE14-1064NM integrates modular design,IP66-rated rugged housing,and breakthrough water-cooled thermal management technology.This ensures consistent performance even in harsh industrial environments—including dust,vibration,and temperature fluctuations—while maintaining the narrow linewidth stability of 1064nm lasers.From automotive part laser marking to semiconductor wafer processing,it bridges the gap between laser source power and application precision.

3.Application Scenarios

A German automotive component manufacturer operated a 1064nm fiber laser system for engine part serial number marking,facing recurring issues with generic scanners:0.2mm marking offset(beyond quality standards)and 30-minute daily downtime due to overheating.After upgrading to SCANLAB INTELLISCANDE14-1064NM systems,the manufacturer achieved transformative results:the scanner’s 5μm repeatability eliminated offset defects entirely,and integrated water cooling reduced thermal downtime to zero.Over 12 months,scrap rates dropped by 85%(from 2.3%to 0.35%),saving$180,000,and marking speed increased by 40%(from 500 characters/second to 700 characters/second),boosting production capacity by 15%.

4.Parameter

Main Parameters

Value/Description

Product Model

SCANLAB SCANde INTELLISCANDE14-1064NM

Manufacturer

SCANLAB GmbH(Laser Scanning Systems Division)

Product Category

High-Precision Galvo Laser Scanner for 1064nm Wavelength

Compatible Laser Wavelength

1064nm(optimized for fiber/solid-state lasers);Tolerance:±10nm

Scanning Performance

X/Y Axis Deflection Angle:±12°;Repeatability:≤5μm;Linear Error:<0.1%FOV

Speed&Latency

Max Scan Speed:10m/s;Command Response Time:<20μs;Update Rate:200kHz

Optical Interface

Beam Diameter:14mm(max);Focal Length Compatibility:100-400mm field lenses

Power Supply

24VDC±10%(2.5A max current);Power Consumption:<30W(50W with cooling)

Cooling System

Integrated Water Cooling(flow rate:0.5L/min);Passive Air Cooling(backup)

Operating Environment

Temperature:5℃~+45℃(operational);-20℃~+60℃(storage);Humidity:10-90%(non-condensing)

Physical Dimensions

180mm(L)×120mm(W)×80mm(H);Weight:1.8kg;Mounting:Flange/Plate

Protection&Durability

Protection Class:IP66;EMC Compliance:EN 61326-1;Shock:25g(11ms)

Safety Features

Integrated Interlock System;Overheat Alarm;Laser Power Shutdown Trigger

Certifications

CE,FDA 21 CFR Part 1040.10,RoHS,IEC 60825-1(Laser Safety)

MTBF(Mean Time Between Failures)

≥1,200,000 hours at 40℃–Minimizes Production Downtime

Diagnostic Functions

Mirror Position Monitoring;Temperature Logging;Cooling System Fault Detection

Compatibility

SCANLAB RTC6 Control Card;1064nm Fiber Lasers(IPG/YLR Series);Industrial PCs

5.Technical Principles and Innovative Values

Innovation Point 1:Water-Cooled Thermal Stability.The INTELLISCANDE14-1064NM features a shell-integrated water cooling channel that maintains scanner temperature within±0.5℃during continuous operation.Unlike air-cooled generic scanners(which drift 2μm/℃),this eliminates thermal-induced marking offset—critical for a South Korean semiconductor plant marking 100μm-wide wafer patterns with 1064nm lasers,reducing pattern distortion by 90%.

Innovation Point 2:Ultra-Low Latency Galvo Control.With a 20μs command response time and 200kHz update rate,it outperforms standard scanners(50μs/100kHz)by 2x.A U.S.battery manufacturer used this for 1064nm laser cutting of electrode sheets:the fast response enabled 0.1mm cut precision at 10m/s speed,increasing electrode yield by 12%vs.previous scanners.

Innovation Point 3:Modular Safety Integration.The built-in interlock system seamlessly connects to industrial safety circuits,automatically shutting down the laser if the scanner malfunctions.A Japanese medical device maker leveraged this for 1064nm marking of surgical tools,ensuring compliance with IEC 60601 standards and avoiding$50,000 in non-compliance fines.

6.Application Cases and Industry Value

Case 1:Semiconductor Wafer Dicing

A Taiwanese semiconductor fab used a 1064nm solid-state laser for 8-inch wafer dicing,struggling with generic scanners that caused 3μm kerf width variation(leading to die breakage).Deploying INTELLISCANDE14-1064NM scanners reduced kerf variation to<0.5μm,cutting die breakage rate from 1.8%to 0.2%.The scanner’s thermal stability also maintained precision during 24/7 operation,increasing wafer throughput by 20%(from 50 to 60 wafers/day)and saving$450,000 annually.

Case 2:Aerospace Component Etching

A French aerospace firm needed to etch 1064nm laser identification codes on titanium turbine blades,facing scanner overheating in high-dust production halls.The INTELLISCANDE14-1064NM’s IP66 protection and water cooling eliminated dust ingress and overheating,reducing unplanned downtime from 8 hours/week to zero.Its 5μm repeatability also ensured code readability under microscopic inspection,passing strict EASA certification and avoiding$200,000 in rework costs.

7.Related Product Combination Solutions

SCANLAB RTC6 Control Card:Scanner Brain–Synchronizes INTELLISCANDE14-1064NM with laser sources.

IPG YLR-1000 Fiber Laser:1064nm Source–Pairs with scanner for high-power marking/cutting.

Thorlabs F220FC-1064 Field Lens:Focus Optic–Expands scanner’s working area to 220mm×220mm.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!