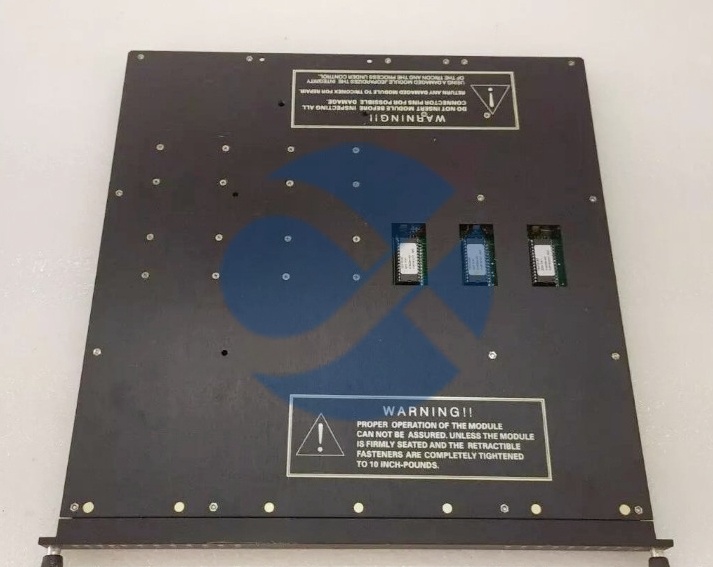

TRICONEX 3604E | TMR Digital Input Module

Description

Description

The TRICONEX 3604Eis a high-integrity,Triple Modular Redundant(TMR)digital input module engineered for critical safety instrumented systems(SIS).Designed to provide the utmost reliability and fault tolerance,this module serves as the primary interface for acquiring discrete field signals—such as emergency stop buttons,pressure switches,and valve limit switches—within a Triconex safety system,ensuring that safety actions are always based on accurate and validated data.

Application Scenarios

In a large ethylene cracker furnace,dozens of critical safety parameters—flame presence,fuel pressure,skin temperature—must be monitored continuously to prevent a runaway reaction or explosion.A single faulty sensor or a glitch in a standard input card could provide a false”safe”signal,disabling vital shutdown logic.This is where the 3604Eproves its worth.Installed in a Triconex safety controller,three independent input channels within the module simultaneously read the status of a single field contact(e.g.,a high-pressure switch).Sophisticated voting logic inside the main processor compares these three readings.Only if at least two channels agree is a valid input state passed to the safety logic solver.This means a transient spike on one wire or a failure of one internal channel cannot cause a spurious trip or,more dangerously,inhibit a necessary shutdown.For the plant safety engineer,deploying the 3604Etranslates to an astronomically lower probability of dangerous undetected failures,directly meeting the core demand of Safety Integrity Level(SIL)3 certification for the most hazardous loops.

Parameter

Main Parameters

Value/Description

Product Model

3604E

Manufacturer

TRICONEX(Schneider Electric)

Product Category

TMR Digital Input Module

Architecture

Triple Modular Redundant(TMR)Three isolated input circuits per point for fault tolerance.

Number of Channels

Typically 8 or 16 points(configurable in groups)Defines how many discrete field devices can be connected.

Input Type

Dry Contact/Voltage-Sourcing(e.g.,24-48 VDC)Accepts signals from switches,relays,or solid-state outputs.

Input Voltage Range

10-60 VDC(Typical,for high-threshold models)Wide range accommodates various plant DC supply voltages.

ON-State Current

Typically 5-10 mA per channel Low current draw minimizes heating and allows use with dry contacts.

Isolation

1500 Vrms Channel-to-Channel and Channel-to-Backplane Prevents fault propagation and ensures signal integrity.

Diagnostic Coverage

>99%(Supports SIL 3)Continuous self-checks detect internal faults like stuck-at conditions.

Response Time

<50 ms(including voting)Fast enough to meet safety response time requirements for most processes.

Communication

Via dedicated TMR bus to main processors Ensures synchronized data transfer to all three voting legs.

Hot Swap Support

Yes Allows replacement without shutting down the safety system.

Certifications

TÜV Rheinland(IEC 61508 SIL 3),ATEX/IECEx(for hazardous areas)Mandatory for use in certified safety systems.

Technical Principles and Innovative Values

Innovation Point 1:True Triple-Channel Sensing with Midpoint Voting.Unlike redundant systems that merely duplicate hardware,the 3604Eimplements genuine TMR at the component level.Each field input is connected to three physically separate and optically isolated sensing circuits on the module.These circuits are powered from independent sources within the system.The”2-out-of-3″voting happens not on the module itself,but in the main TMR processors.This architecture ensures that a common-mode failure(like a power surge on the field wiring)affecting one or even two channels can be identified and masked,guaranteeing that a valid signal is still available to initiate the safety function.

Innovation Point 2:Comprehensive Online Diagnostics(IooD).The module continuously performs Internal Diagnosis(IooD),a concept critical for high SIL ratings.It doesn’t just read the input;it tests the entire measurement path.This includes checking for field wire breaks(by monitoring loop current),detecting shorts to ground or voltage,and verifying the health of its own internal opto-isolators and circuitry.Any discrepancy or fault is immediately reported to the main processors and can be configured to drive the input to a predefined safe state(e.g.,de-energized),preventing a dangerous”fail-undetected”scenario.

Innovation Point 3:Defined Failure Modes and Hot-Swapability.The 3604Eis designed with predictable failure modes.If a fault is detected,the module can clearly communicate its failure state.Combined with hot-swap capability,this allows a maintenance technician to identify and replace a faulty module during a plant’s online operation without compromising the safety system’s protection.The remaining two good channels in other modules continue to provide the required fault tolerance during the swap,maximizing system availability—a crucial balance between safety and production continuity.

Application Cases and Industry Value

Case Study:Offshore Gas Compression Platform Safety Upgrade.An aging offshore platform’s fire and gas(F&G)detection system,along with its emergency shutdown(ESD)system,relied on single-channel input cards.A risk assessment mandated an upgrade to a SIL 2/SIL 3 system.A new Triconex safety system was installed,with the 3604Emodules chosen as the digital input interface for all critical initiators:flame detectors,gas detectors,manual emergency stops,and process pressure switches.

During commissioning,a previously undetectable intermittent ground fault on a gas detector circuit was immediately flagged by the 3604E’s diagnostics,preventing what could have been a nuisance trip or a blind spot later.In operation,the system provided unmatched visibility:operators could see not just the state of each switch,but also the health of the wiring and the input module itself.Several months post-installation,a lightning-induced surge damaged one channel on a module monitoring a wellhead pressure switch.The system remained operational(due to the other two good channels),logged the fault clearly,and allowed the module to be replaced at the next planned maintenance window without an unplanned production shutdown.The platform manager cited the diagnostic capability and fault tolerance of the 3604Eas key factors in achieving both higher safety integrity and improved operational uptime.

Related Product Combination Solutions

3603E:The complementary TMR Digital Output Module.It receives voted commands from the safety logic solvers and drives final elements(solenoid valves,motor starters)with the same high level of redundancy and diagnostics.

3805E/3806E/3808E:The TMR Main Processors.These are the brains that execute the safety logic and perform the voting on the input data provided by the 3604E.

3503E:The TMR Communication Module.Facilitates communication between the main processors and I/O modules like the 3604E,and can also handle peer-to-peer communication with other Tricon systems or DCS.

4351B:A TMR Analog Input Module.Used when the safety function requires monitoring of continuous variables(e.g.,pressure,temperature)alongside the discrete signals handled by the 3604E.

9753-810/9753-410:Redundant Power Supplies.Provide the isolated,high-quality DC power required by the 3604Eand other system components,completing the fault-tolerant architecture.

Trilogger/TriStation 1131:The engineering software suite.Used to configure the I/O mapping,diagnostics,and voting parameters for the 3604E,and to program the safety logic in the main processors.

Installation,Maintenance,and Full-Cycle Support

Installation of the 3604Erequires meticulous attention to the principles of safety system engineering.Field wiring must be segregated from other cabling,properly shielded,and grounded at a single point to prevent noise and ground loops.Each field device should be connected to the three independent terminal blocks on the module as per the detailed wiring diagrams.Configuration is done using TriStation 1131 software,where each channel is assigned properties like debounce time,fault state(0 or 1),and included in the appropriate voting group.

Maintenance is heavily reliant on the system’s powerful diagnostic tools.Routine tasks involve reviewing system diagnostics logs to identify any developing issues like increasing channel disagreement or intermittent faults.The modules themselves require no periodic calibration.The hot-swap procedure is well-defined:using the software,the specific module is placed in a”remove”state,its LED indicators confirm it is safe to extract,it is replaced,and the new module is automatically recognized and integrated by the system.

We provide end-to-end support for TRICONEX 3604Eand Triconex safety systems.Our services encompass initial system design consultation,SIL verification support,installation supervision,and comprehensive training for your engineering and maintenance teams.We maintain a stock of genuine Triconex modules and can provide expedited delivery for critical spares.Our technical experts are available to assist with troubleshooting,system audits,and migration projects from legacy systems,ensuring your safety instrumented functions remain robust and compliant throughout their lifecycle.

Contact us for a safety system audit,to discuss your SIL compliance needs,or for reliable supply of Triconex safety components.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!