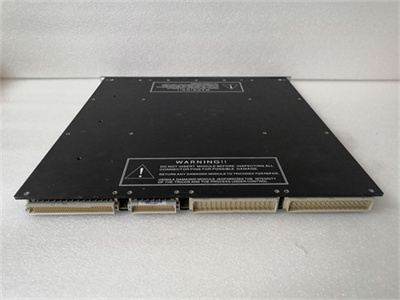

TRICONEX 3625 Triconex Communication Module for Secure DCS/SCADA Integration

Description

The TRICONEX 3625 is a high-reliability Network Interface Module(NIM)developed by Schneider Electric(formerly part of Invensys)for the Tricon™and Triconex®safety instrumented systems(SIS).Designed to enable secure,redundant communication between the triple-modular redundant(TMR)Tricon controller and external supervisory systems—such as DCS,HMI,or asset management platforms—the TRICONEX 3625 ensures continuous data flow without compromising functional safety integrity.It supports real-time diagnostics,hot-swap capability,and compliance with IEC 61508/61511 up to SIL 3.

Application Scenarios

At a major LNG export terminal in Qatar,plant engineers needed to integrate their legacy Tricon v10 safety system with a new Emerson DeltaV DCS for unified alarm management—without introducing single points of failure.By deploying dual TRICONEX 3625 modules in redundant configuration,they established a fault-tolerant communication path that continuously published safety interlock statuses,trip events,and diagnostic data via Modbus TCP.When one network cable was accidentally severed during maintenance,the system seamlessly failed over to the secondary TRICONEX 3625,preventing any loss of visibility into critical ESD(Emergency Shutdown)logic.This implementation not only met API 750 and IEC 61511 requirements but also eliminated weekly manual log checks—saving over 200 engineering hours annually.

Parameter

Main Parameters Value/Description

Product Model TRICONEX 3625

Manufacturer Schneider Electric(Triconex brand)

Product Category Network Interface Module(NIM)for Safety Instrumented Systems

Communication Ports Dual 10/100 Mbps Ethernet(RJ-45),isolated

Redundancy Support Full dual-module redundancy with automatic failover

Protocols Supported Modbus TCP(Server),Tricon proprietary protocols(e.g.,TCI,TDC)

Safety Integrity Level Certified to IEC 61508 SIL 3/IEC 61511

Hot-Swap Capability Yes—field-replaceable without powering down the Tricon chassis

Diagnostics Built-in LED status indicators+real-time health reporting to TriStation 1131

Mounting Inserted into Tricon Main Chassis(v10/v11)–occupies one I/O slot

Operating Temperature 0°C to+60°C

Certifications CE,UL 61010-2-201,ATEX(optional),IECEx(optional),RoHS

Technical Principles and Innovative Values

Innovation Point 1:True Dual-Channel Redundancy Architecture–Unlike standard Ethernet cards,the TRICONEX 3625 operates in synchronized pairs within the TMR framework.Both modules actively monitor network health,and if one fails,the other assumes full communication duty within milliseconds—ensuring zero interruption to safety-critical data streams.

Innovation Point 2:Safety-Isolated Data Path–All communication is routed through the Tricon’s triple-channel voter logic before transmission.This prevents corrupted or malicious external data from influencing safety decisions,maintaining the integrity of the TMR core.

Innovation Point 3:Unified Engineering Experience–The TRICONEX 3625 is fully configurable via TriStation 1131 software,allowing engineers to define data tags,update rates,and security filters without third-party tools—reducing integration risk and validation effort.

Innovation Point 4:Cybersecurity by Design–Supports MAC address filtering,port lockdown,and optional VLAN segmentation.No open ports or web services are exposed,aligning with IEC 62443 principles for OT security.

Application Cases and Industry Value

In a European refinery undergoing a digital transformation initiative,the safety team faced regulatory pressure to provide real-time proof of SIF(Safety Instrumented Function)availability to auditors.By installing redundant TRICONEX 3625 modules on all 12 Tricon racks,they enabled live streaming of valve positions,solenoid statuses,and proof-test results to a cloud-based compliance dashboard.Over two years,this system reduced audit preparation time from 3 weeks to 2 days and contributed to a 30%reduction in unplanned shutdowns due to early detection of degraded final elements.

Another deployment at a nuclear power plant in the U.S.used the TRICONEX 3625 to securely relay reactor protection system(RPS)statuses to the main control room HMI—while keeping the safety logic physically and logically isolated from the plant network.The module’s deterministic response(<100 ms update cycle)and SIL 3 certification satisfied NRC regulatory requirements,setting a benchmark for future safety-system integrations.

Related Product Combination Solutions

TRICONEX 3503E:Main processor module for Tricon v10—requires TRICONEX 3625 for external communication.

TRICONEX 3635:Higher-performance NIM with fiber-optic option—ideal for electrically noisy environments where TRICONEX 3625 may face EMI challenges.

TRICONEX 4329A:Analog output module often monitored via TRICONEX 3625 for remote setpoint verification in closed-loop safety applications.

Schneider Electric TriStation 1131:Engineering workstation software used to configure,test,and diagnose TRICONEX 3625 communication parameters.

TRICONEX 3700E:Power supply module that ensures stable operation of TRICONEX 3625 during brownout conditions.

TRICONEX 3615:Serial communication module—used alongside TRICONEX 3625 when legacy devices require RS-485 connectivity.

TRICONEX 3511:Digital input module whose trip signals are frequently published via TRICONEX 3625 to enterprise historians.

Schneider Electric Triconex Enhanced Diagnostic Monitor(EDM):Software suite that leverages TRICONEX 3625 data for predictive maintenance and SIL verification.

Installation,Maintenance,and Full-Cycle Support

Installing the TRICONEX 3625 requires insertion into a designated slot in a Tricon v10 or v11 main chassis,followed by configuration in TriStation 1131 to define IP addresses,data tags,and protocol settings.For redundancy,two modules must be installed and linked via the chassis backplane—no external cabling is needed for synchronization.The unit supports hot-swap,enabling replacement during live operation without triggering a system halt,provided the redundant partner is healthy.

Maintenance is simplified by front-panel LEDs indicating Power,Link,Activity,and Fault status.Comprehensive diagnostics—including CRC errors,packet loss,and temperature—are logged internally and accessible via TriStation or EDM.Our support team provides validated firmware images,network topology templates,and cybersecurity hardening guides tailored to your industry(e.g.,oil&gas vs.pharma).Every TRICONEX 3625 we supply undergoes full functional testing with live Tricon hardware,including redundancy failover simulation and Modbus TCP stress testing,backed by an 18-month warranty and lifetime technical consultation.

![]()