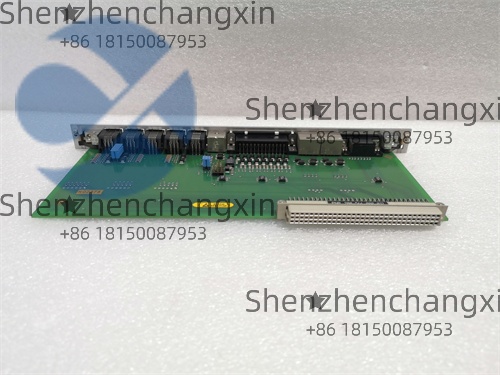

Vibro-meter IOCN Card 200-566-000-012 Industrial Vibration Monitoring

200-566-000-012/200-566-101-012 Technical Specifications

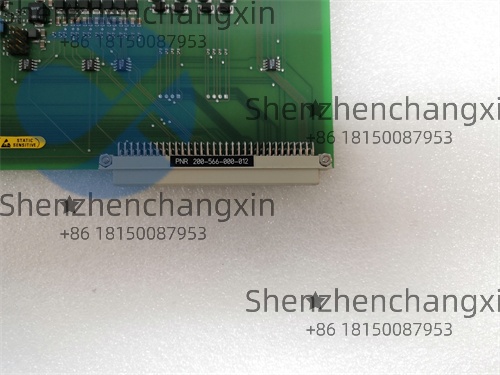

Product Model:200-566-000-012(Main Card)/200-566-101-012(Auxiliary Card or Variant)

Manufacturer:Vibro-meter(now part of Emerson)

Product Type:IOCN(Input/Output Communication Node)Card

System:VM600 Shaft Condition Monitoring System

Function:System communication and I/O data exchange core

Supply Voltage:24VDC(+20%/-15%)

Power Consumption:≤15W

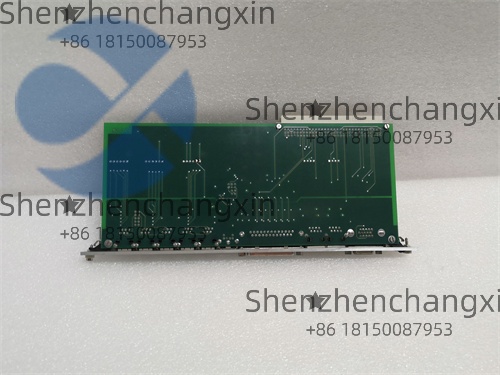

Mounting Method:Standard DIN Rail Mounting

Operating Temperature:-20°C to+70°C

Storage Temperature:-40°C to+85°C

Protection Rating:IP20(module body)

Communication Interface:Dual-redundant Ethernet,RS-485

Supported Protocols:Modbus RTU/TCP,EtherNet/IP(configuration required)

Data Throughput:Up to 10 Mbps

Compatibility:Seamless integration with VM600 series sensors,power cards,and computing cards

200-566-000-012/200-566-101-012 Product Overview

Hey everyone,the Vibro-meter 200-566-000-012 and Vibro-meter 200-566-101-012 are no ordinary communication modules;they are the”information master”of the VM600 shaft condition monitoring system!The 300,000-kilowatt steam turbine in your factory,the centrifugal compressor supplying gas to the chemical plant—their”vital signs”—vibration,shaft displacement,key phase,and speed—all rely on the Vibro-meter 200-566-000-012 IOCN card to collect,package,and transmit data.

The Vibro-meter 200-566-000-012’s core role is to serve as a”bridge”between the sensor front end and the host computer.On one end,it connects to”scouts”like eddy current sensors and accelerometers,collecting millisecond-level vibration data in real time.On the other end,it connects to the DCS,PLC,or higher-level monitoring software,transmitting critical status information and receiving commands from the control system.This card supports redundant communication and dual-port hot standby.Even if one link is disconnected,data continues to flow,ensuring uninterrupted monitoring.It not only transmits data but also performs preliminary logical analysis and alarm output,serving as the”cerebral cortex”of the entire condition monitoring system(CMS).

The Vibro-meter 200-566-101-012 is typically a specific version or function expansion card for use with the 200-566-000-012.It may have slight differences in firmware,communication protocols,or I/O configurations,and is designed for specific projects or system upgrades.These two cards work together in the VM600 chassis to form a highly reliable,real-time industrial monitoring network.

Main Features and Advantages

The Vibro-meter 200-566-000-012 IOCN card is incredibly stable,accurate,and fast!First,it features a highly reliable design specifically designed for harsh industrial environments.It offers a wide operating temperature range,strong electromagnetic interference(EMI)immunity,and overvoltage and reverse polarity protection for 24/7 uninterrupted operation,making it a world class performer compared to office network cards.

Second,it offers high-speed,real-time data acquisition.Supporting multi-channel simultaneous sampling at a high sampling rate,the Vibro-meter 200-566-000-012 can detect subtle rotor vibration changes and be sensitive to early signs of faults(such as minor misalignment and bearing wear),truly preventing problems before they occur.This card utilizes an industrial-grade processor and real-time operating system(RTOS),ensuring fast response and low latency.

Third,it offers powerful communication capabilities.It supports dual redundant Ethernet networks,configurable for hot standby or load balancing,ensuring a secure data link.It also supports mainstream industrial protocols such as Modbus RTU/TCP,enabling easy integration with various DCS(such as Emerson Ovation and Honeywell Experion)and SCADA systems,enabling data sharing and eliminating information silos.

Fourth,it offers modularity and scalability.As part of the VM600 system,the Vibro-meter 200-566-000-012 can be flexibly combined with other I/O cards,power cards,and computing cards to create complete solutions ranging from simple monitoring to complex analysis.The system supports online replacement(hot plugging and unplugging),facilitating maintenance without affecting other channels.

Fifth,it offers powerful diagnostic capabilities.The card features built-in LED status indicators,displaying real-time status information such as power,operation,communication,and faults.Detailed diagnostic logs can also be viewed through the host software,allowing for quick problem location and saving time and effort.Simply put,this card is a hardcore device designed for the health management of critical rotating equipment.

The Vibro-meter 200-566-000-012 IOCN card is the communication and data acquisition backbone of the VM600 shaft condition monitoring system.Engineered for mission-critical rotating machinery,it delivers high-speed,real-time collection of vibration,displacement,and speed signals with exceptional reliability.Featuring dual redundant Ethernet ports and support for industrial protocols like Modbus and EtherNet/IP,the Vibro-meter 200-566-000-012 ensures uninterrupted data flow to control systems even in harsh environments.Its modular design integrates seamlessly within the VM600 rack,enabling scalable monitoring solutions for turbines,compressors,and pumps.With robust diagnostics and hot-swappable capability,this I/O communication node minimizes downtime and maximizes asset availability,making it an indispensable component for predictive maintenance and operational safety in heavy industry.

Application areas

Vibro-meter 200-566-000-012 and The 200-566-101-012’s primary focus is monitoring the heart of rotating equipment.In large thermal or nuclear power plants,it’s installed in the monitoring cabinet of a steam turbine generator set,monitoring every vibration of the shaft system 24/7.Any abnormality detected immediately triggers an alarm,preventing catastrophic failures or shaft fractures.

In petrochemical companies’ethylene plants,centrifugal compressors are the”heart”equipment,with a single day of downtime costing millions.The Vibro-Meter 200-566-000-012 monitors vibration trends in real time and,combined with expert systems,enables predictive maintenance,shifting maintenance from”fixing when broken”to”fixing when nearing failure,”significantly improving operational efficiency.In the propulsion systems of offshore platforms and large ships,as well as the main motors of rolling mills in steel mills,these IOCN cards are crucial for ensuring equipment safety and preventing unplanned downtime.Without them,even the best sensors are useless,rendering the entire condition monitoring system blind.

Selection Guide/Purchasing Recommendations

If you’re replacing your Vibro-meter 200-566-000-012 or 200-566-101-012,first determine if you’re using a standard VM600 system.These two cards cannot be interchanged.Verify the complete model number of the spare part on site,especially the suffix number,as it may indicate a different firmware version or communication configuration.Check the jumper settings and IP address of the existing card.Ensure the new card is pre-configured to avoid misidentification.It’s strongly recommended to purchase the complete kit with genuine,authorized software;otherwise,activation or communication may not be possible.Avoid buying second-hand,disassembled parts.Aging or configuration loss on these delicate communication cards can cause systemic failures.Remember,the”nerves”of a condition monitoring system must be genuine,original components to ensure undistorted signals.

Frequently Asked Questions(FAQs)

Q:Are the 200-566-000-012 and 200-566-101-012 interchangeable?

A:Not necessarily.The Vibro-meter 200-566-101-012 may be a variant or upgrade for a specific project.The firmware version and system configuration must be verified;it is not directly interchangeable.

Q:Which DCS systems does the card support?

A:The Vibro-meter 200-566-000-012 supports Modbus RTU/TCP and can be connected to mainstream DCS systems.For OPC or specific protocols,a gateway or host configuration is required.

Q:Can it be hot-swapped?

A:Yes.The VM600 system supports hot-swapping,but it is recommended to perform this operation during non-critical system operations to avoid data jitter.

Q:How do I update the firmware?

A:This requires Vibro-meter-specific software(such as the VM600 Toolkit)to update via Ethernet or serial port.This operation requires professional assistance.

Q:Will the system still function without this card?

A:No.The Vibro-Meter 200-566-000-012 is the system’s communication core.If it is missing,sensor data cannot be uploaded,paralyzing the entire monitoring function.

Related Products

200-501-000-012:VM600 Power Supply Card,provides power to the rack.

200-550-000-012:VM600 Computing Card,responsible for data processing and algorithm analysis.

VM600:Mainframe of the Shaft Condition Monitoring System.

240-001-000-012:Eddy Current Sensor,used for shaft vibration measurement.

241-001-000-012:Accelerometer,used for bearing housing vibration measurement.

200-560-000-012:Relay Output Card,used for alarm contact output.

200-570-000-012:4-20mA output card,analog signal transmission.

VM600 Toolkit:System configuration and diagnostic software.

Emerson Ovation:Commonly integrated DCS system.

Bently Nevada 3500:Competitive system.

Pre-installation preparation:Before replacing the Vibro-meter 200-566-000-012,confirm that the system configuration has been backed up.Prepare the configuration documentation,laptop,and dedicated software.Verify that the new card model is identical to the old one,especially the firmware version.Wear an anti-static wrist strap to prevent static electricity from damaging the precision chip.

Maintenance recommendations:Check the card LED light regularly.A solid green light indicates normal operation;a flashing or solid red light indicates a fault.Regularly check communication status and data quality using the software.When cleaning,use dry compressed air to blow through the heat dissipation holes;never wipe with a damp cloth.When replacing a card,disconnect the host computer first,remove the card,and then insert the new card.Restart the system and verify communication in the following order.Remember,the Vibro-meter 200-566-000-012 is the lifeblood of the system,so operate it with stability,precision,and determination.