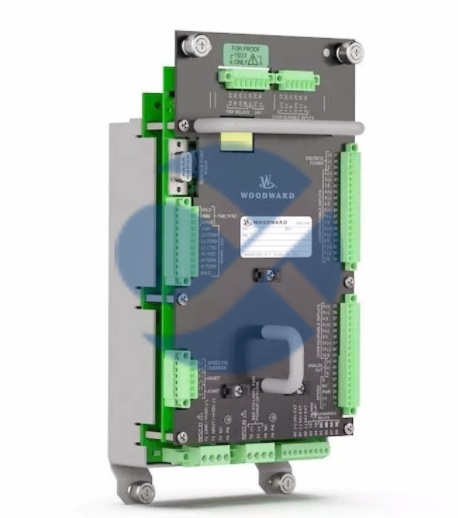

WOODWARD 5501-471 | Speedtronic Governor Card

Description

The WOODWARD 5501-471is a critical governor control module from Woodward’s extensive portfolio,designed specifically for precise speed regulation and protection of prime movers like gas turbines,steam turbines,and diesel engines.This advanced control card integrates sophisticated algorithms with robust hardware to ensure stable operation,optimal efficiency,and unwavering safety in demanding power generation and mechanical drive applications.

Application Scenarios

Consider a remote offshore platform where a gas turbine-driven generator provides all electrical power.Any instability in turbine speed could cascade into voltage and frequency fluctuations,jeopardizing sensitive drilling equipment and platform safety systems.Here,the 5501-471acts as the guardian of rotational stability.It continuously monitors turbine speed via magnetic pickups,compares it against the precise setpoint,and calculates corrective adjustments to the fuel valves within microseconds.During a sudden load rejection—if a large compressor trips—the module’s rapid overspeed protection logic intervenes instantly,commanding the fuel valves to close at a predetermined rate to prevent a dangerous runaway condition.For the facility engineer,this translates to guaranteed power quality,protected capital assets,and the confidence that the turbine will respond predictably to the grid’s most demanding transients.

Parameter

Main Parameters

Value/Description

Product Model

5501-471

Manufacturer

Woodward

Product Category

Governor Control Module/Turbine Control Card

Primary Function

Speed Control&Overspeed Protection The core purpose:maintaining precise shaft speed and acting as the primary defense against catastrophic overspeed.

Compatible System

Woodward MicroNet,NetCon,or 505/505E Platforms Indicates the digital control system family this module is designed to integrate with.

Input Signals

Speed(from magnetic pickups),Load Demand,Various Process Analog/Digital Signals Accepts the necessary feedback and command signals to perform its control functions.

Output Signals

Actuator Drive Signals(typically to Electro-Hydraulic Converters),Alarm/Shutdown Relays Executes control decisions by driving final elements and initiating protective actions.

Control Algorithms

PID with customizable gain scheduling,Isochronous/Droop Load Sharing Provides flexible and precise control tuning for various operating modes and grid conditions.

Overspeed Trip Setting

User-configurable,typically 110-120%of rated speed Defines the critical threshold at which an emergency shutdown is triggered to protect the turbine.

Operating Temperature

0°C to+60°C(Standard Industrial Range)Suited for installation in protected control enclosures.

Communication Interface

Proprietary Backplane to Main Controller Ensures high-speed,deterministic data exchange within the Woodward control system.

Key Certifications

Complies with relevant UL,CE,and marine standards(where applicable)Ensures suitability for global industrial and offshore applications.

Technical Principles and Innovative Values

Innovation Point 1:Deterministic,Dedicated Control Loop.Unlike a generalized PLC handling multiple tasks,the 5501-471is engineered for a singular,mission-critical purpose:speed regulation.Its hardware and firmware are optimized to execute the speed control algorithm with minimal latency and absolute determinism.This dedicated architecture ensures that the fuel valve command is calculated and issued on every scan cycle without fail,a reliability level essential for protecting multi-million dollar turbomachinery.

Innovation Point 2:Adaptive Control with Gain Scheduling.The module employs sophisticated Proportional-Integral-Derivative(PID)control logic where the tuning parameters(gains)can be dynamically adjusted based on operating points like speed or load.This means the 5501-471provides tight,stable control whether the turbine is at idle,ramping up,or operating at full load—overcoming the limitation of fixed-gain controllers that are only optimal at one condition.

Innovation Point 3:Integrated Multilayer Protection.Beyond basic control,the 5501-471incorporates layered protection logic.The primary overspeed protection is often a separate,hardwired”last-defence”function within the module.It monitors speed independently and can initiate a fuel cut-off via dedicated outputs,providing a safety-critical layer that is functionally distinct from the regulatory control software,aligning with best practices in machinery protection.

Application Cases and Industry Value

Case Study:Enhancing Grid Stability for a Peaking Power Plant.A utility operating aeroderivative gas turbines for peak shaving faced challenges with slow response times and occasional instability when units were dispatched rapidly to meet sudden grid demand.They retrofitted their control systems with newer Woodward governors featuring the 5501-471control module.

The implementation allowed for much finer tuning of the droop and acceleration control parameters.The improved processing speed of the 5501-471enabled faster detection of grid frequency deviations and quicker calculation of fuel corrections.As a result,the turbines could now accept a 50%load step in under 30 seconds with minimal frequency excursion,compared to over 2 minutes previously.This transformed the units from mere peakers to valuable assets for grid frequency regulation(ancillary services),generating significant new revenue streams for the operator.The plant manager credited the predictable,robust performance of the new control hardware,including the 5501-471,for unlocking this operational and financial flexibility.

Related Product Combination Solutions

9907-XXX Series:The main Woodward digital governor controller(e.g.,9907-167).The 5501-471module is a key component that plugs into this main unit,providing the specific speed control functionality.

Electric Actuators or EHC Valves(e.g.,EGCP,EGBP series):These are the final control elements driven by the output signals from the 5501-471.They physically modulate fuel flow to the turbine.

Magnetic Speed Pickups(MPUs):Critical sensors that provide the raw speed feedback signal to the 5501-471.Their signal quality and reliability are paramount for accurate control.

ProTech 203 Overspeed Protection System:While the 5501-471has primary overspeed protection,a dedicated system like the ProTech 203 can provide an independent,SIL-rated layer of safety,creating a robust 2-out-of-3 protection scheme.

Toolkit Software:Woodward’s configuration and tuning software.This is used to commission,monitor,and adjust the parameters of the 5501-471and the entire governor system from a laptop.

Load Sharing Modules(e.g.,8237-xxx):When multiple turbines/gen-sets operate in parallel,these modules work in conjunction with the 5501-471to ensure proportional load distribution between units.

Installation,Maintenance,and Full-Cycle Support

Installation of the 5501-471is performed as part of the broader Woodward governor system.It involves carefully inserting the module into its designated slot on the main controller backplane,ensuring proper alignment and seating.Pre-commissioning requires loading the correct application-specific firmware and configuration file using Toolkit software.Critical steps include verifying the calibration of connected speed sensors and performing a thorough simulation test of the control and protection logic before connecting to live actuators.

Maintenance is predominantly predictive and software-based.Technicians can use the Toolkit software to monitor the health of the 5501-471,track performance trends,and read out detailed event logs following any trips or alarms.Physical maintenance is minimal due to the solid-state design but includes periodic checks of connector integrity and ensuring the control cabinet environment remains within specifications.Spare module strategy is crucial;having a pre-configured 5501-471on hand allows for swift replacement during planned outages,minimizing downtime.

We provide comprehensive lifecycle support for the WOODWARD 5501-471and associated systems.Our services range from initial application engineering and system design support to on-site commissioning assistance and operator training.We maintain access to genuine Woodward components and firmware updates.Our technical team can assist with troubleshooting,performance optimization,and legacy system upgrades,ensuring your turbomachinery controls operate at peak reliability and efficiency for years to come.

Contact us for expert advice on turbine control solutions,spare part provisioning,or to discuss a performance upgrade for your existing Woodward equipment.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!