Description

The ABB REG670 is a versatile and advanced numerical protection relay belonging to the Relion® 670 series. Designed primarily for line differential and feeder protection in electrical power systems, it provides comprehensive security for transmission and sub-transmission lines. This device integrates multiple protection, control, measurement, and monitoring functions into a single compact unit, supporting modern communication protocols like IEC 61850 for seamless integration into digital substations.

Communication: IEC 61850. IEC 60870-5-103/104. Modbus

Operating Temperature: -40°C to +70°C

Power Supply: 48-250 V DC / 110-230 V AC

Protection Functions: Differential, Distance, Overcurrent, Auto-reclosing

Product Detailed Description

REG670 Technical Specifications

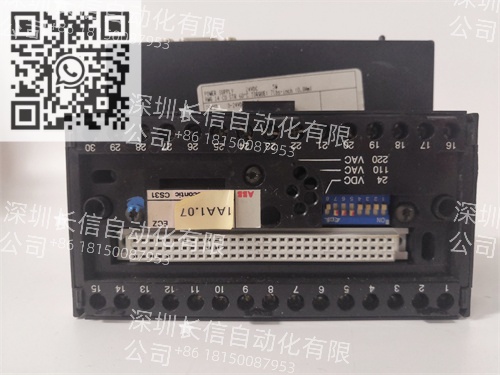

Product Model: REG670

Manufacturer: ABB

Product Type: Numerical Protection Relay / Feeder Terminal

Protection Functions:

Line Current Differential (87L)

Distance Protection (21)

Overcurrent Protection (50/51. 50N/51N)

Breaker Failure Protection (50BF)

Auto-reclosing (79)

Control & Monitoring:

Four-quadrant energy/power metering (P, Q, S, PF, Hz)

Sequence-of-Events (SOE) recorder

Disturbance recorder

Circuit breaker condition monitoring

Communication Protocols:

Station Bus: IEC 61850-8-1 (GOOSE, MMS), IEC 60870-5-103/104

Process Bus: IEC 61850-9-2LE (Sampled Values) optional

Other: Modbus RTU/TCP, DNP3

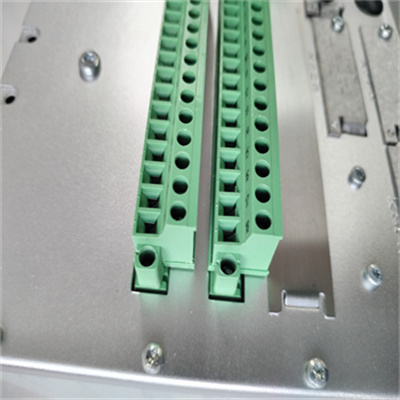

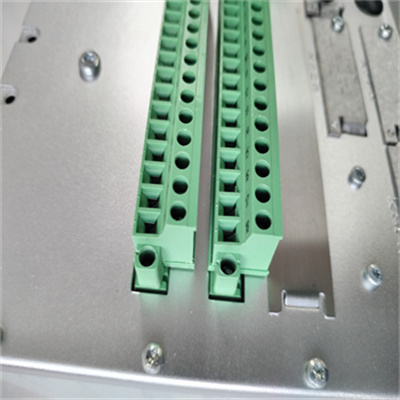

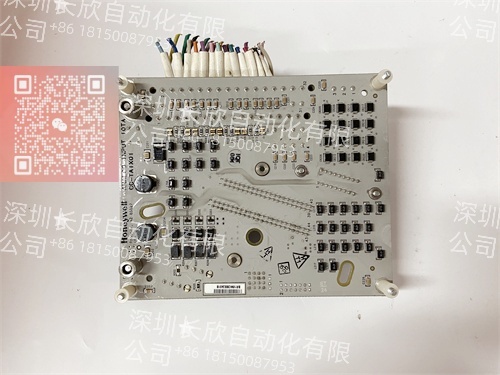

Hardware Interfaces:

Ethernet ports (RJ45 & ST fiber)

Serial communication ports (RS485/RS232)

Binary Inputs/Outputs (configurable)

Power Supply: 48-250 V DC / 110-230 V AC

Operating Temperature: -40°C to +70°C

Certifications: IEC 60255. IEEE C37.90. ANSI, GOST

REG670 Product Overview

The ABB REG670 is a flagship numerical relay within ABB’s Relion® product family, engineered to be the intelligent guardian of medium to high-voltage transmission and distribution lines. It goes beyond a simple protection device, acting as a complete bay control unit (BCU) for feeder applications. Its core protection philosophy is anchored by its high-speed, pilot-wire based or communication-assisted line differential protection (87L), which provides unit protection—meaning it acts only for faults within its protected zone, offering ultimate selectivity and speed. The ABB REG670 also incorporates full-scheme distance protection (21) with multiple zones as a reliable backup, making it exceptionally secure against communication channel failures. This combination makes it a cornerstone for modern grid resilience, ensuring faults are isolated quickly and precisely to maintain overall network stability and minimize outage impact.

Main Features and Advantages

Unmatched Protection Selectivity and Speed: The REG670’s primary strength is its line differential protection (87L). By comparing the current entering and leaving a protected line segment in real-time (using dedicated fiber-optic channels or pilot wires), it can detect internal faults with extreme sensitivity and trip instantaneously, without intentional time delay. This “unit protection” scheme is inherently selective, as it does not operate for external faults, allowing for faster fault clearing and improved system stability compared to traditional time-graded overcurrent schemes.

Comprehensive Functionality in a Single Platform: The REG670 consolidates multiple devices into one. Beyond core protection, it offers advanced auto-reclosing (79) for overhead lines, power quality monitoring (e.g., for voltage sags/swells), and detailed energy metering compliant with standards like IEC 62053-22. This integration reduces panel space, wiring complexity, and overall system cost while providing a unified data source for SCADA and asset management systems.

Future-Proof Communication and Integration: As a native digital device, the REG670 is built for the modern IEC 61850 substation automation ecosystem. It supports GOOSE (Generic Object Oriented Substation Event) messaging for fast, peer-to-peer communication between relays (e.g., for interlocking or breaker failure initiation) and MMS for client-server data reporting. Support for process bus (IEC 61850-9-2LE) via optional modules future-proofs installations, enabling connection to merging units and eliminating traditional copper wiring for CT/VT signals.

Robust Design for Demanding Environments: Engineered for the harsh reality of substations, the REG670 operates reliably across a wide temperature range from -40°C to +70°C. Its design includes robust filtering algorithms and hardware hardening to withstand electromagnetic interference (EMI) and transients, ensuring dependable operation during switching events or fault conditions.

Application Scenarios

In a critical 230 kV transmission corridor, two REG670 relays are installed at opposite ends of a 50 km line, connected via a dedicated fiber-optic link. When a phase-to-ground fault occurs due to a fallen tree, both relays instantly calculate the differential current. Within one cycle, they exchange data, confirm the fault is internal, and issue simultaneous trip commands to their respective circuit breakers. The fault is cleared in under 100 ms, preventing generator instability and a potential cascading outage. The relay’s integrated disturbance recorder captures pre- and post-fault waveforms, providing engineers with crucial data for analysis. At a large industrial plant, a single REG670 protects the main incoming feeder. Its sensitive ground-fault protection detects an evolving cable insulation failure. The relay’s programmable logic allows it to first issue an alarm for planned maintenance, preventing an unexpected outage that would halt production.

Selection and Purchasing Advice

When selecting an ABB REG670. the first step is to define the primary protection requirement. For two-ended or multi-terminal lines where maximum speed and selectivity are needed, its differential protection (87L) is the key feature. For applications requiring backup protection or where a communication channel is not available, ensure the distance protection (21) scheme is appropriately configured. Critically, verify the required communication interfaces (fiber type, protocols like IEC 61850 or DNP3) and the needed number of binary inputs/outputs for interlocking and control. Always plan the configuration using ABB’s PCM600 software to ensure all application logic and settings are considered before procurement.

Frequently Asked Questions (FAQ)

Q: What communication channels can be used for the differential protection (87L)?

A: The REG670 supports multiple channels for differential protection, including direct fiber-optic connections, multiplexed fibers over a telecom network, or traditional pilot wires. The choice depends on available infrastructure, distance, and required data transmission speed/reliability.

Q: Can the REG670 function as a standalone bay controller?

A: Absolutely. Beyond protection, the REG670 includes extensive control and interlocking logic capabilities via its Flexible and Configurable Logic (FCL). It can handle local breaker control, synchronism check, and interlocking with other bays, often eliminating the need for a separate PLC or control unit.

Q: How is the relay configured and maintained?

A: Configuration, setting, and analysis are performed using ABB’s dedicated PCM600 engineering software. This tool provides an intuitive interface for setting protection parameters, designing control logic, retrieving fault records, and updating firmware.

Related Products

ABB RET670: Transformer protection relay, often used in conjunction with the REG670 for complete substation protection schemes.

ABB REC670: Generator protection relay, part of the same 670 series family for protecting power generation assets.

ABB REB670: Busbar protection relay, providing fast differential protection for substation busbars, complementing feeder protection.

ABB RER670: Feeder management relay for distribution applications, a sibling product with a focus on overcurrent and earth-fault protection.

ABB PCM600: The essential configuration and parameter setting tool for the entire Relion 670 series, including the REG670.

ABB FOX615: A communication interface/network switch often used in substation networks to facilitate IEC 61850 communication for devices like the REG670.

Installation and Maintenance

Installation Preparation: Prior to installing the REG670. ensure the panel cutout dimensions and mounting arrangement are correct. Verify the power supply voltage matches the relay’s ordered variant (DC or AC). All current transformer (CT) and voltage transformer (VT) circuits must be shorted before connecting to the relay. For differential protection, plan and test the communication channel (fiber path or pilot wires) thoroughly before commissioning.

Maintenance Suggestions: Regular maintenance involves checking the relay’s self-diagnostics via its front interface or PCM600. The health of the CT circuits should be monitored using the relay’s measured current values and supervision functions. Periodically download and review disturbance records and event logs. Ensure the relay’s clock is synchronized via IRIG-B or SNTP for accurate time-stamping of events. Keep a backup of the relay’s configuration file (SGR) in PCM600 after any changes.

Product Assurance

We guarantee that every ABB REG670 relay supplied is a genuine ABB product, fully traceable and compliant with the original specifications. Our technical support can assist with integration planning and application guidance. For a robust and future-proof protection solution for your critical assets, partner with us.

We stand behind the quality of every ABB REG670 protection relay we provide. Our expertise ensures you receive not only the product but also the necessary support for a successful implementation in your protection and control system.