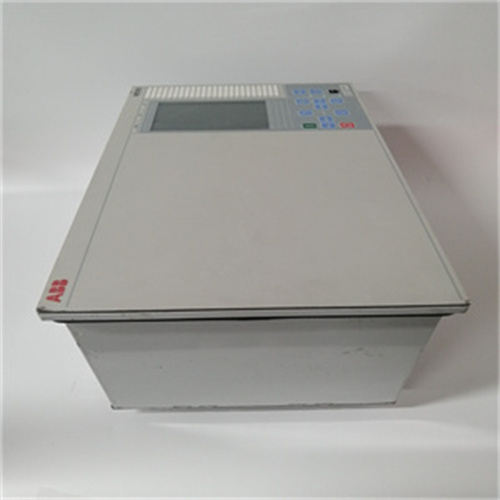

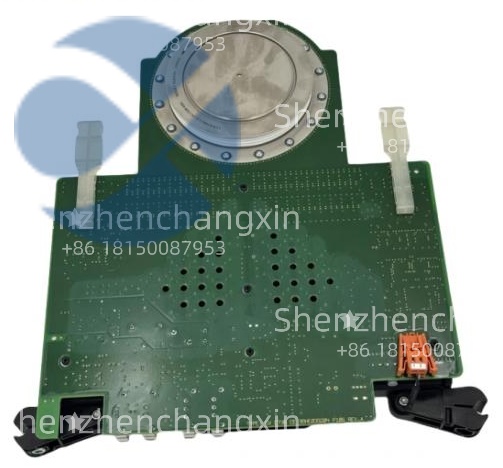

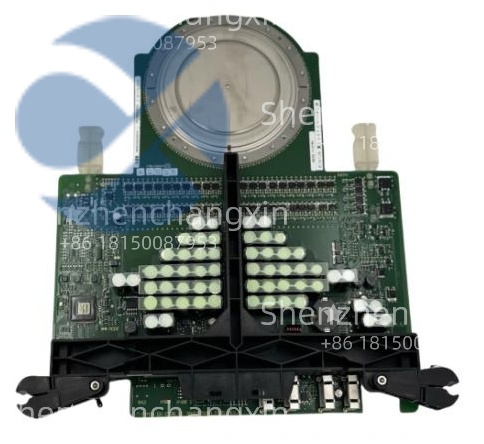

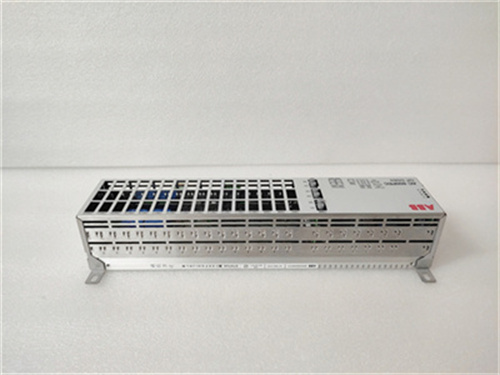

ABB PFTL101B 5.0KN 3BSE004191R1

The ABB PFTL101B 5.0KN 3BSE004191R1 is a high-performance magnetostrictive tension sensor manufactured by ABB, also known as a Pressductor PillowBlock Load Cell, designed specifically for high-range tension measurement and control in industrial automation applications.

Core Functions and Technical Parameters

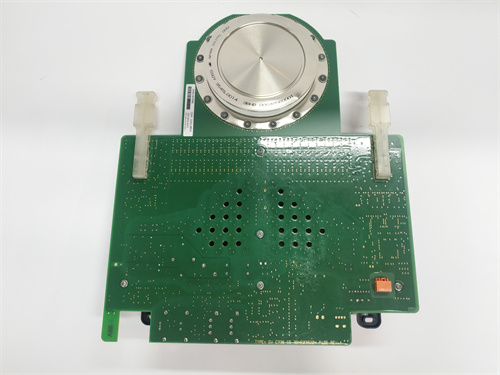

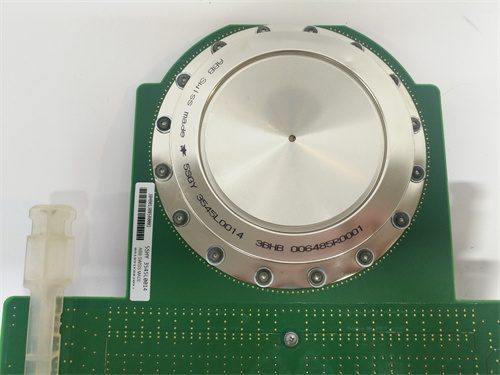

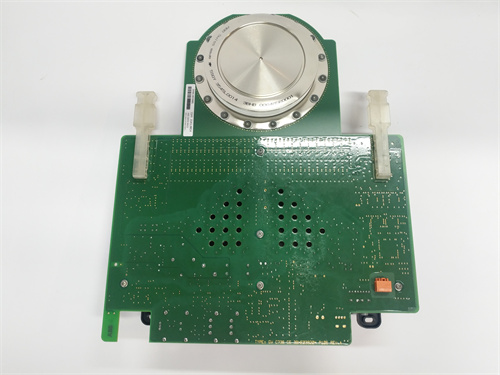

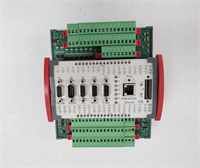

This sensor operates on the principle of magnetostriction, converting changes in magnetic properties due to applied force into an electrical signal for real-time tension measurement. Key technical parameters include: a measuring range of 5.0 kN (5000 N), suitable for high-range tension applications; IP67 protection rating, providing excellent dust and water resistance, enabling stable operation in harsh environments such as high temperature, low temperature, and high humidity; accuracy class ±0.5%, with excellent linearity and repeatability; operating temperature range of -20℃ to +80℃; and output signal support for fieldbus interfaces such as Profibus, allowing seamless integration with ABB tension controllers and other control systems.

The structural design utilizes high-strength materials such as stainless steel and alloy steel, with dimensions of 25mm × 25mm × 100mm and a weight of approximately 0.5 kg, resulting in a compact and robust structure. The sensor allows a lateral load of 30.0 kN, a measurement direction overload capacity of 25.0 kN, a displacement of 0.015 mm, and a spring constant of 325 kN/mm.

Application Scenarios and Industry Value

This sensor is widely used in the pulp and paper industry (paper machines, calibrators, coating machines, rewinders), metal processing, textile and light industry, aerospace, and mechanical manufacturing. In the paper industry, it accurately measures high tension during the paper drying stage, preventing paper breakage or wrinkling and ensuring printing registration accuracy; in the metal processing field, it is suitable for the initial processing of steel strips and aluminum materials, controlling high tension to prevent material deformation and improve product quality.

Technical Advantages

This sensor utilizes magnetostrictive technology, offering fast dynamic response and high static torque, effectively avoiding resonance and noise problems associated with traditional sensors at low speeds. The integrated design simplifies the installation process and ensures stable operation in normal environments. Its high precision, high reliability, and broad industry applicability make it a preferred product in metal processing, papermaking, light industry, and other sectors. ABB provides detailed product manuals and technical documentation covering installation, commissioning, maintenance, and troubleshooting steps. These resources are available through the official ABB website or authorized distributors, ensuring optimal performance and long-term stability of the sensors.

Choose Shenzhen Changxin for peace of mind and worry-free after-sales service! Large stock available, same-day shipping via SF Express!!!