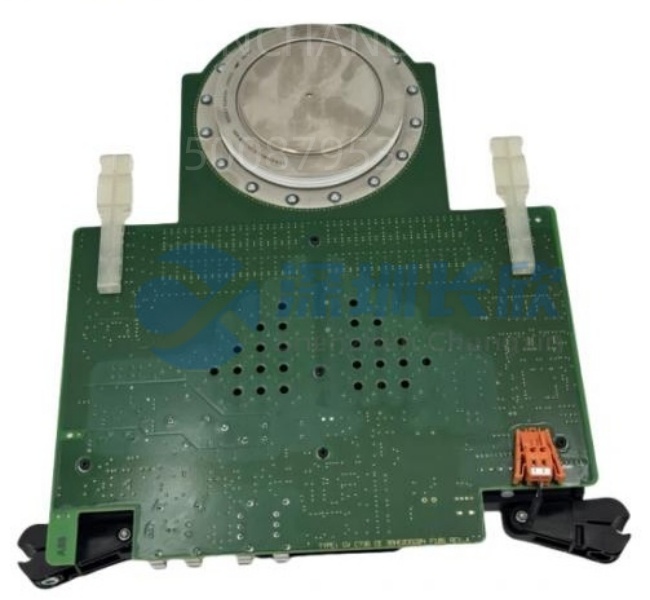

ABB PFEA113-65 3BSE050092R65

📊 Technical Specifications

The table below consolidates the key technical parameters of the ABB PFEA113-65 3BSE050092R65 tension electronics unit.

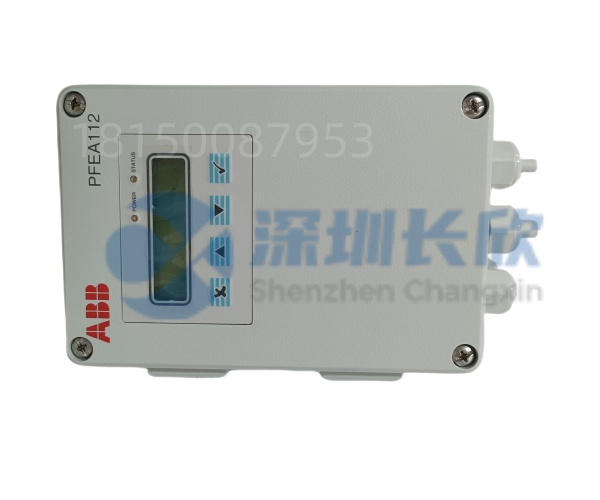

📝 Product Overview

The ABB PFEA113-65 3BSE050092R65 is a high-precision tension controller designed for industrial automation. It acts as the “brain” for maintaining precise material tension in continuous web processing applications . Its primary function is to interface with load cells, process tension signals, and output control signals to actuators like brakes or drives, ensuring consistent material tautness to prevent breaks, wrinkles, or stretching . It is important to note that one source describes this model as an analog input module for the ABB S800 I/O platform ; however, the majority of sources consistently identify it as a tension controller, which is its primary and most recognized function.

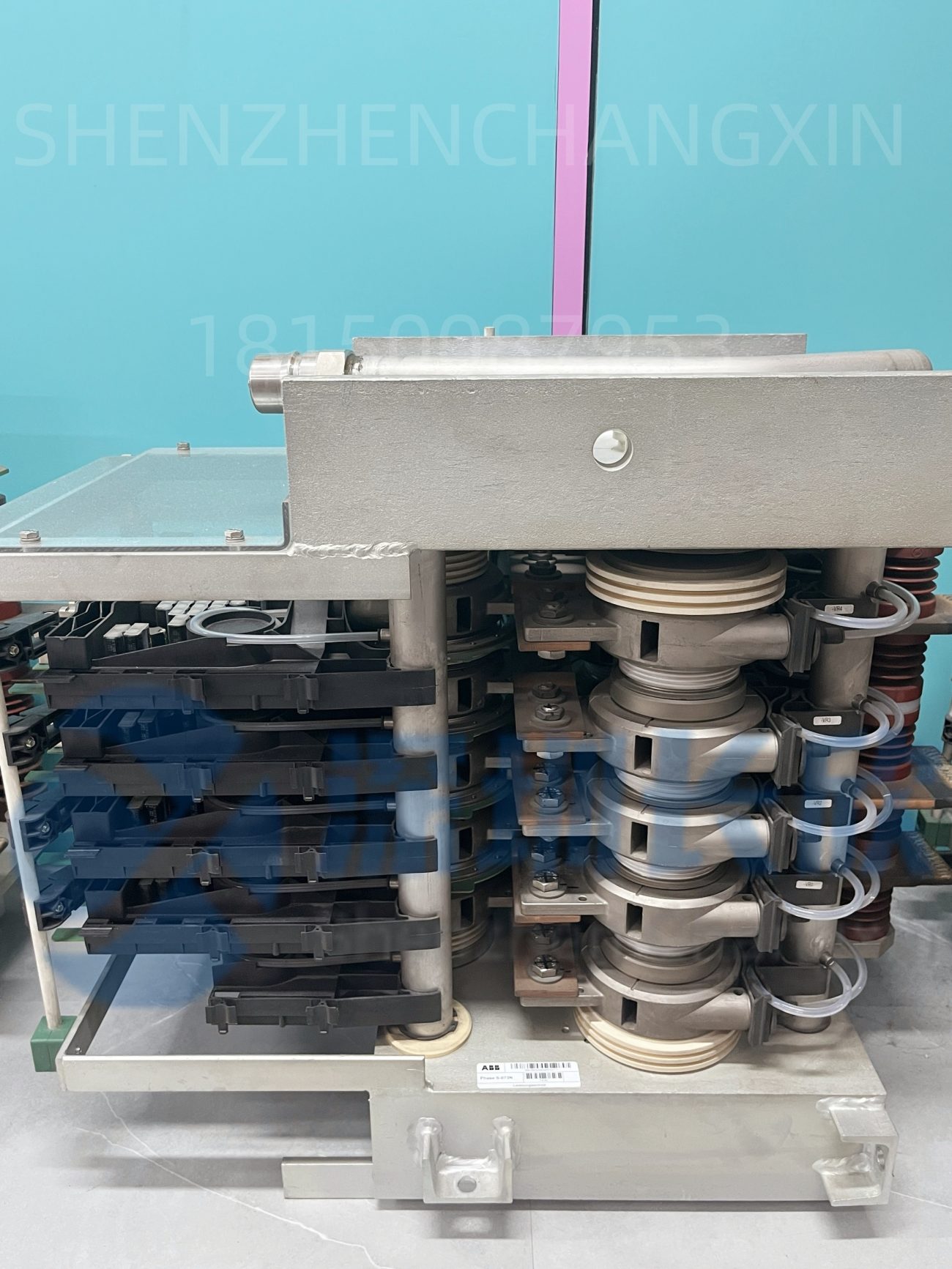

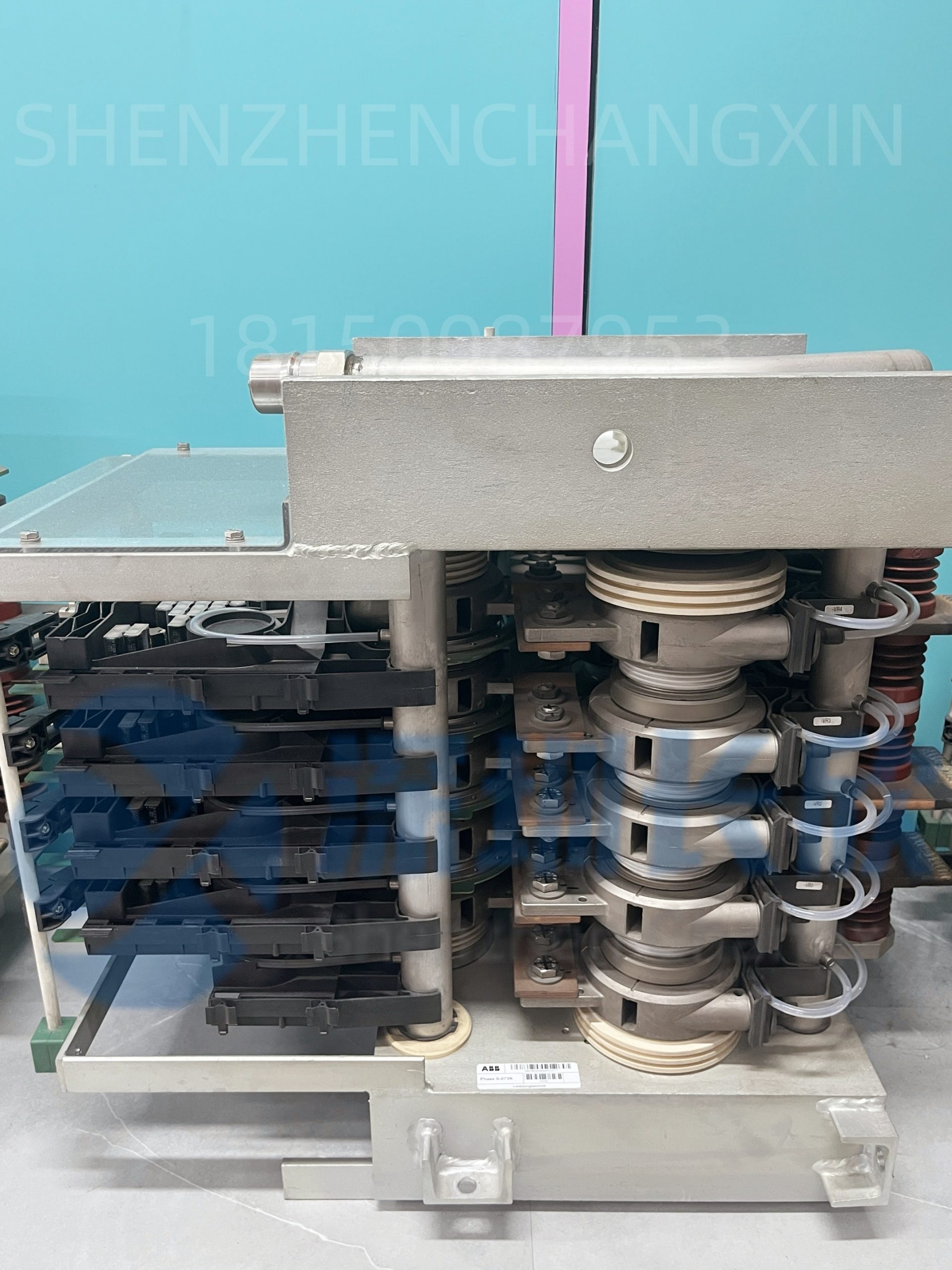

⚙️ Core Functions and Design

The module is engineered for reliability in demanding industrial environments. Its design centers on acquiring accurate data from up to four load cells and providing flexible control outputs . A key feature is its PROFIBUS-DP communication interface, which allows for seamless integration into larger PLC or DCS systems for centralized monitoring and control . The module includes a self-diagnostic function to aid in troubleshooting and maintenance. Its robust enclosure, with either an IP65 rating for harsh environments or an IP20 rating for protected cabinets, ensures protection against dust and moisture . The high accuracy of ±0.1% and a fast response time of less than 10 milliseconds enable it to maintain stability in high-speed production processes .

🏭 Application Scenarios

The ABB PFEA113-65 is critical in industries that process continuous web materials where consistent tension is vital for product quality and operational efficiency . Typical application areas include:

Pulp and Paper: Controlling tension in paper machines, winders, and coaters to prevent breaks and ensure uniform thickness .

Printing and Packaging: Maintaining accurate tension on paper, film, or foil in printing presses to prevent misregistration and stretching .

Textiles and Plastics: Managing yarn, fabric, and plastic film tension during production, winding, and converting operations .

Metal Processing: Precisely controlling the tension of metal strips and coils in rolling mills and slitting lines to prevent deformation .

🛠️ Installation and Maintenance

Proper installation and maintenance are crucial for optimal performance. Before installation, it is essential to consult the official ABB documentation and ensure all power is disconnected and locked out (LOTO) for safety . Wiring should be done carefully, using shielded cables for load cells and communication lines to minimize electromagnetic interference . For maintenance, regular inspection of the module and its connections for dust, looseness, or corrosion is recommended. The module’s built-in self-diagnostics should be monitored for early fault detection. Periodically checking the calibration of the associated load cells is also advised to maintain long-term measurement accuracy .

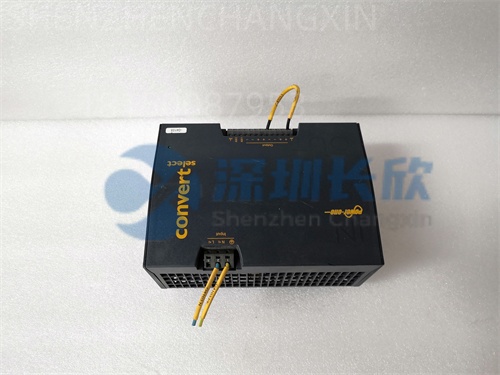

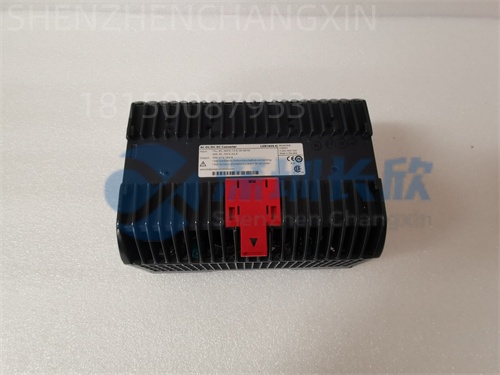

💡 Support and Warranty

Multiple suppliers indicate that the ABB PFEA113-65 3BSE050092R65 is available new with original packaging and is typically backed by a 12-month warranty . For complex issues, contacting certified ABB service technicians or reputable automation parts suppliers is recommended to ensure reliable support .