YOKOGAWA MAC2-B Available: Isolator for 4-20mA, TC, RTD & DC Voltage

Description

The YOKOGAWA MAC2-B is a highly versatile, loop-powered signal conditioner and isolator module, part of Yokogawa’s renowned MAC2 series. It is a fundamental building block in process control systems, designed to convert, isolate, and transmit various analog signals—such as 4-20mA, thermocouple, RTD, and DC voltage—ensuring accurate and reliable data acquisition by control systems.

Application Scenarios

In a chemical processing plant, a critical reactor’s temperature, measured by a Type J thermocouple, must be accurately transmitted 200 meters to the central DCS control room. The raw millivolt signal is weak, susceptible to electrical noise from pump motors, and the sensor ground differs from the control room ground, creating a ground loop potential. The YOKOGAWA MAC2-B is installed right at the field junction box. It takes the fragile thermocouple signal, amplifies and linearizes it, provides galvanic isolation to break the ground loop, and outputs a robust, noise-immune 4-20mA current signal perfectly suited for the long cable run. The MAC2-B solves the critical pain points of signal degradation, ground loop errors, and sensor-to-system compatibility, ensuring the operator sees the true reactor temperature, which is vital for safe and efficient process control.

Technical Principles and Innovative Values

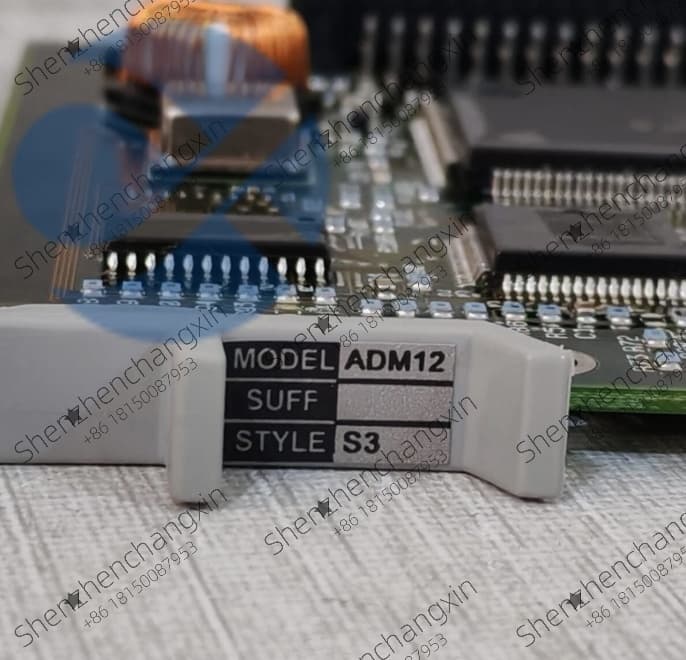

Innovation Point 1: True Universal Simplicity via Range Codes. The MAC2-B eliminated the need for hardware jumpers, potentiometers, or different module types for different signals. Its input type and range are set purely via a 4-digit range code dialed in on the front. This revolutionary approach meant a single, universal module could be stocked for hundreds of applications, drastically simplifying engineering design, procurement, and maintenance. A technician could reconfigure a signal point from a thermocouple to a 4-20mA input in seconds without opening the panel.

Innovation Point 2: Robust 2-Wire Loop-Powered Isolation. The module’s ability to provide full 1500V galvanic isolation while being powered entirely from the 4-20mA output loop is a significant feat of efficient design. It draws a tiny amount of operating power from the loop, requiring no separate power supply wiring. This dramatically reduces installation cost and complexity, especially in large systems with hundreds of points, while still providing complete protection against ground loops and noise that could corrupt critical measurements.

Innovation Point 3: High-Density, High-Reliability Design. Packing this level of functionality—signal conversion, linearization, cold junction compensation (for TCs), and isolation—into a compact, rugged, and passively cooled DIN-rail module was a major advancement. The high component density and reliable design led to exceptional mean time between failures (MTBF), making the MAC2-B a “set-and-forget” component in control panels, trusted for decades of maintenance-free service in harsh industrial environments.

Application Cases and Industry Value

A large offshore oil platform was experiencing persistent, fluctuating errors in its crude oil export flow measurements. The readings differed between the field transmitter and the control room, causing disputes during custody transfer. The issue was traced to massive ground potential differences and electrical noise across the platform. The solution was to retrofit YOKOGAWA MAC2-B isolators at the field input cards of the control system. The high level of isolation (1500V) broke the ground loops, and the robust design rejected the electrical noise. The result was an immediate stabilization and alignment of the flow signals. The project engineer stated: “Installing the MAC2-B modules was the most cost-effective upgrade we performed. It resolved a years-long measurement uncertainty issue overnight, ensuring accurate fiscal metering and saving us from potential revenue loss and reconciliation disputes.”

Related Product Combination Solutions

Yokogawa DCS/PLC I/O Cards (e.g., for CENTUM CS 3000. FA-M3): The control system input cards that receive the clean, isolated 4-20mA signal from the MAC2-B.

Field Transmitters: The source devices (e.g., pressure, flow, temperature transmitters) whose signals are conditioned by the MAC2-B.

DIN Rail Power Supply: Provides the 24VDC or other loop power for the output side of the MAC2-B isolators.

Yokogawa Recorders & Indicators: Devices like the HR2500 or UT/UP series that can display signals processed through a MAC2-B.

DIN Rail Terminal Blocks & Housings: The physical mounting and wiring accessories used to install banks of MAC2-B modules neatly in a panel.

Yokogawa Field Wireless Equipment: In modern setups, the conditioned 4-20mA signal from a MAC2-B could be fed into a wireless transmitter for remote monitoring.

Installation, Maintenance, and Full-Cycle Support

Installation of the YOKOGAWA MAC2-B is straightforward, contributing to its popularity. It snaps onto a standard 35mm DIN rail. Field wiring (input) and control system wiring (output) connect to its clearly marked screw terminals. The most critical step is setting the correct 4-digit range code on the front dials according to the desired input type and span. Once powered from the output loop, the module is operational. No software or calibration is typically required, as accuracy is inherent to the design.

Maintenance is minimal due to its solid-state, high-reliability design. The primary task is occasional verification of the input signal and output current with a precision multimeter to confirm the module is scaling correctly. If a fault is suspected, swapping the module with a spare is a quick diagnostic step due to its universal, plug-and-play design. We provide comprehensive support for this industry workhorse. We can supply new old stock (NOS) or expertly refurbished MAC2-B modules tested to original specifications. Our technical team can assist with range code selection, wiring diagrams, and troubleshooting guidance to ensure your legacy or ongoing systems maintain perfect signal integri

Description

Description