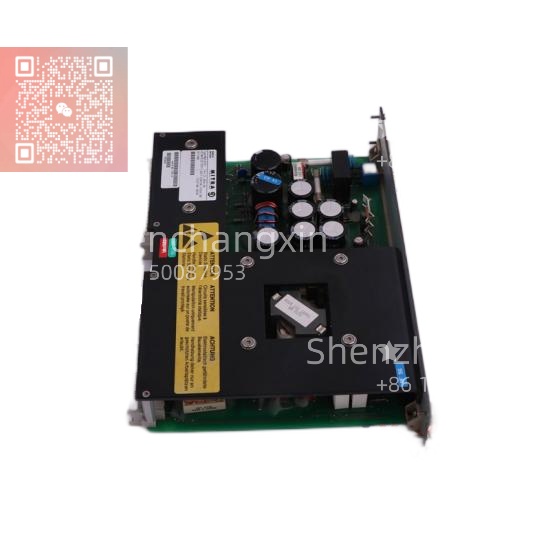

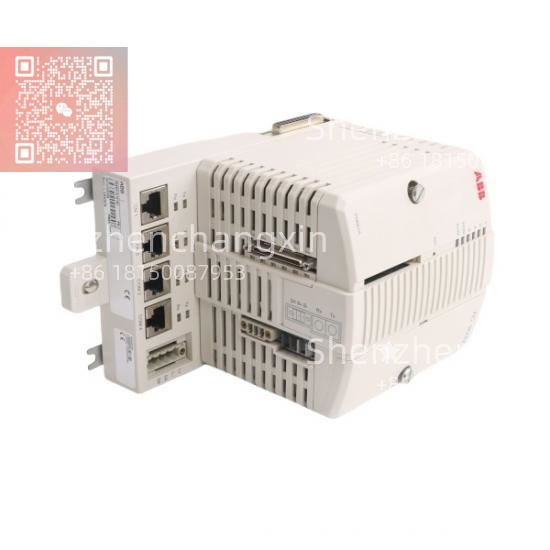

ABB PPC907BE | Industrial Power Supply with Integrated Diagnostics (Order Code: 3BSE013244R1)

Description

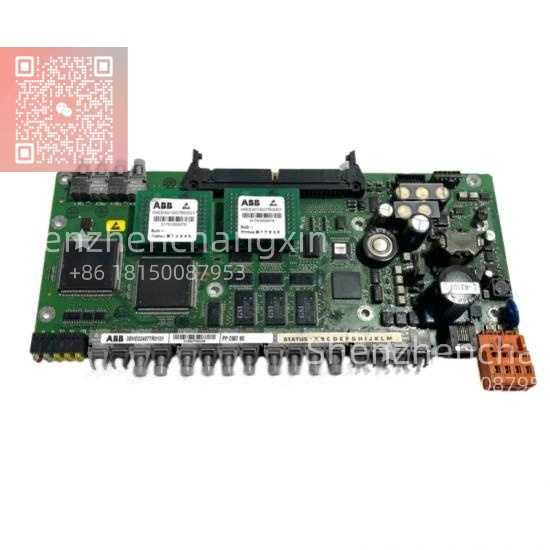

The PPC907BE is a high-reliability, 24V DC industrial power supply module developed by ABB for use in the AC 800M and System 800xA automation platforms. Delivering a stable 10A output with wide-range AC input, integrated protection features, and support for redundant configurations, the PPC907BE ensures uninterrupted power to PLCs, I/O modules, and field devices—even in electrically noisy or thermally challenging environments.

Engineered for continuous operation, this fanless, DIN-rail-mountable unit combines robustness, efficiency, and intelligent diagnostics to minimize downtime and simplify maintenance in critical control applications.

Application Scenarios

At a nuclear power plant in Finland, regulatory requirements demanded zero single-point failures in safety-related control cabinets. Engineers selected dual ABB PPC907BE power supplies in parallel-redundant mode to feed all S800 I/O modules managing reactor coolant monitoring. During a routine grid disturbance that caused a momentary brownout, one PPC907BE automatically compensated for the other’s brief voltage dip—keeping all sensors online without triggering a scram. “The redundancy worked flawlessly,” noted the instrumentation lead. “No alarms, no logs, just silent resilience.” This real-world performance underscores how the PPC907BE delivers not just power—but peace of mind in life-safety systems.

Parameter

表格

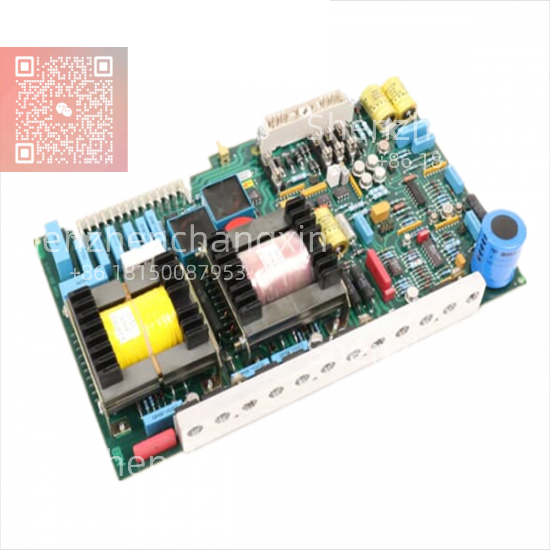

Technical Principles and Innovative Values

Innovation Point 1: True Universal Input – The PPC907BE operates seamlessly from 85V AC (brownout conditions) to 264V AC (high-line regions), eliminating the need for region-specific variants or external transformers in global deployments.

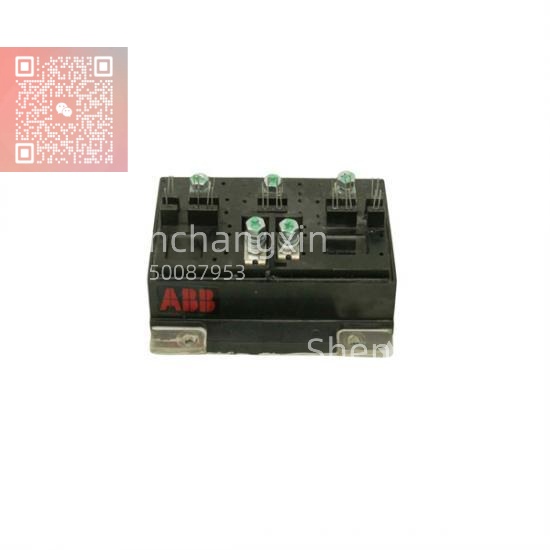

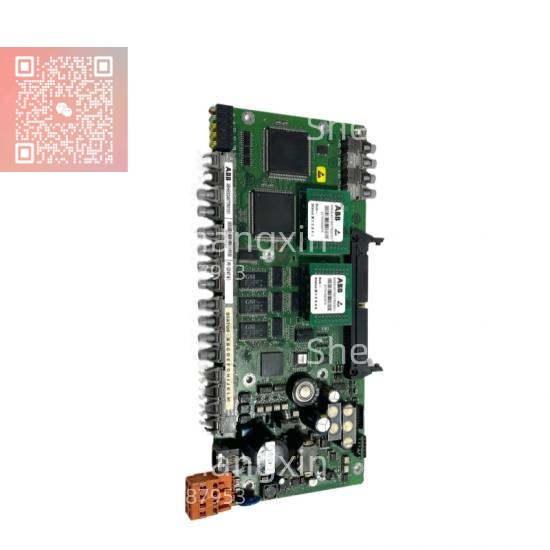

Innovation Point 2: Intelligent Fault Signaling – Dual LEDs provide immediate visual feedback: green confirms stable 24V output; red illuminates during overvoltage, overtemperature, or short-circuit events—accelerating troubleshooting without tools.

Innovation Point 3: Silent, Maintenance-Free Operation – The fanless design removes a common failure point, making the PPC907BE ideal for dust-prone or sterile environments (e.g., pharma cleanrooms or coal handling plants).

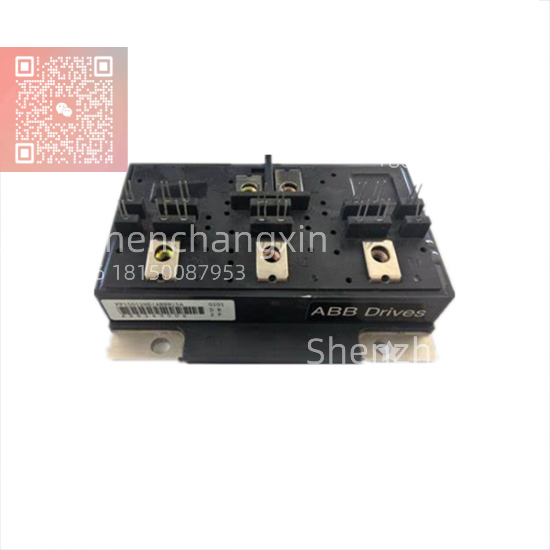

Innovation Point 4: Seamless Redundancy Integration – When paired with ABB’s PDP910 diode redundancy module, two PPC907BE units can share load and auto-failover within milliseconds—ensuring 99.999% power availability.

Application Cases and Industry Value

In a Chilean copper mine operating at 4.000 meters altitude, conventional power supplies overheated due to thin air and ambient temperatures exceeding 45°C. After switching to the PPC907BE, the site reported zero power-related outages over two years. Its convection cooling and wide temperature tolerance proved decisive. Similarly, in a German automotive stamping plant, the PPC907BE powers safety PLCs and light curtains on robotic presses. During a hydraulic leak that flooded a control cabinet, the unit’s short-circuit protection prevented cascading damage—allowing production to resume within hours instead of days. Users consistently highlight its “install-and-forget” reliability.

Related Product Combination Solutions

PDP910: Diode redundancy module – enables hot-standby or load-sharing between two PPC907BE units.

PM866K02: AC 800M CPU – relies on stable 24V from PPC907BE for deterministic control execution.

S800 I/O Modules (e.g., AI810. DO810) – powered via backplane by PPC907BE through system power distribution.

TU845: Terminal base – often installed in same cabinet as PPC907BE for complete I/O power architecture.

TB850 / TB851: CPU baseplates – require clean 24V supply from PPC907BE for reliable controller operation.

CI854: PROFIBUS module – benefits from low-noise output of PPC907BE for stable field communication.

SNAT 7780: Security gateway – can be powered from same PPC907BE rail in compact security cabinets.

XO08R1: Relay output module – draws coil power from PPC907BE’s robust 24V bus.

Installation, Maintenance, and Full-Cycle Support

Installing the PPC907BE requires mounting it on a standard 35 mm DIN rail, connecting AC input wires to the spring-clamp terminals, and linking the 24V DC output to the system power bus (typically via terminal blocks or power distributors). For redundant setups, connect two PPC907BE units to a PDP910 diode module before feeding the load. Ensure adequate clearance (≥20 mm on both sides) for natural convection cooling.

Maintenance is minimal: periodically verify LED status and clean surface dust in high-particulate areas. No calibration or firmware updates are needed. As an ABB-authorized partner, we supply only genuine PPC907BE units (3BSE013244R1), each tested for output stability, overload response, and thermal performance. All units include a 12-month warranty, full traceability, and access to engineering support for redundancy design or lifecycle management.

Contact us for a customized solution—whether you’re building a new 800xA system, hardening legacy panels, or securing spares for critical infrastructure, the PPC907BE delivers clean, resilient, and intelligent power for the backbone of industrial automation.