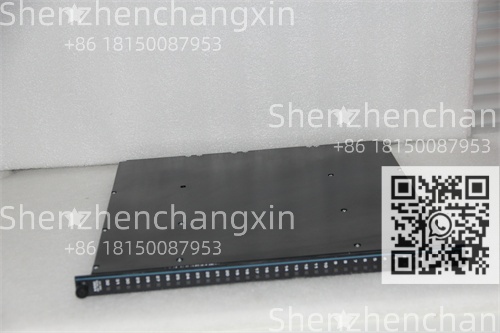

ABB AI810 – S800 I/O Module for AC 800M DCS in Oil, Gas & Power Applications

📄 Product Overview

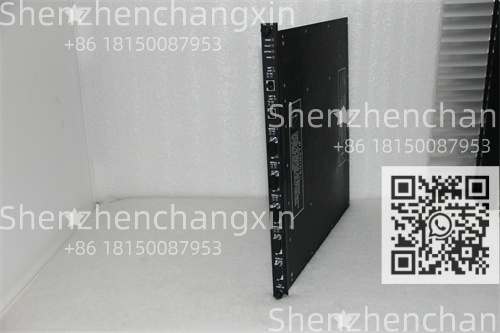

The ABB AI810 is an 8-channel analog input (AI) module in the S800 I/O family, designed for use with the AC 800M programmable automation controller (PAC) within ABB’s System 800xA distributed control system (DCS). It interfaces field instruments—such as pressure transmitters, temperature sensors (via isolators), flow meters, and level gauges—by accepting standard 4–20 mA or 0–20 mA current signals.

Engineered for high reliability and precision, the AI810 supports HART communication, channel-level diagnostics, and optional redundant configuration, making it suitable for both basic process control and IEC 61508 SIL 2 safety-related applications.

🏭 Typical Application Scenario

At a natural gas compressor station in Norway, operators needed to monitor suction/discharge pressures and bearing temperatures across six turbines. They deployed ABB AC 800M controllers with AI810 modules to read signals from HART-enabled Rosemount pressure transmitters and RTD-to-4–20 mA converters. Using Control Builder M, engineers configured each channel independently—some for 4–20 mA with HART pass-through, others for 0–20 mA. During a routine maintenance window, a technician used a HART communicator through the AI8110 + HM810 HART multiplexer to calibrate a transmitter without interrupting the control loop. When a bearing temperature spiked due to lubrication failure, the AI810’s fast scan (<100 ms) enabled the turbine to trip safely before damage occurred. “The AI810 gives us both accuracy and intelligence,” said the lead controls engineer.

⚙️ Key Technical Specifications

表格

💡 Technical Advantages & Innovations

✅ Per-Channel Configuration

Each of the 8 channels can be independently set to 4–20 mA or 0–20 mA via Control Builder M—no hardware jumpers needed.

✅ HART Transparency

When paired with the HM810 HART Multiplexer, enables asset management systems (e.g., ABB Ability™ Asset Suite) to read device diagnostics without disrupting control.

✅ Redundant I/O Ready

Can be used in dual-redundant AC 800M systems for critical loops—ensuring continuous operation during module or controller faults.

✅ Integrated Diagnostics

Reports open circuits (e.g., broken wire), sensor drift, and signal out-of-range—reducing troubleshooting time.

✅ Seamless 800xA Integration

Auto-detected in System 800xA, with faceplate graphics, alarm management, and historical trending out of the box.

🔗 Commonly Paired Products

Controller: AC 800M (PM86x series)

Communication Interface: CI854A (PROFIBUS DP), CI864 (Modbus RTU)

HART Multiplexer: HM810 (enables HART on AI810/AO810)

Power Supply: SA811 (I/O bus power)

Terminal Base: TB820 (screw terminals), TB840 (spring clamp)

Software: Control Builder M, System 800xA Engineering

Field Devices: ABB, Emerson, Endress+Hauser 4–20 mA/HART transmitters

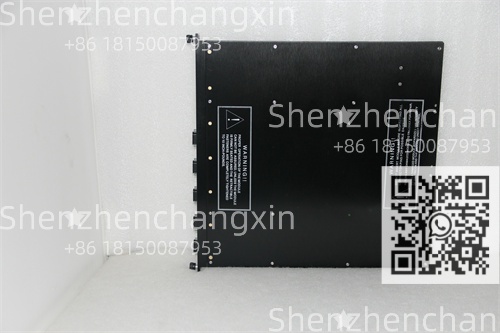

🔧 Installation & Best Practices

Wiring: Use twisted, shielded pair cables; ground shield at controller end only.

Loop Power: Ensure field devices have adequate loop voltage (≥12 V at transmitter).

Redundancy Setup: Requires two AI810 modules, dual CI854A, and redundant AC 800M CPUs.

HART Enablement: Install HM810 on the same I/O bus; configure HART addresses in Control Builder M.

Diagnostics: Enable “open circuit detect” in channel parameters for dry-contact simulation or fault detection.

⚠️ Obsolescence & Lifecycle Note

The AI810 remains actively supported by ABB and is widely deployed globally. While newer platforms like ABB Ability™ System 800xA with Compact I/O exist, the S800/AI810 platform is still recommended for large-scale, high-reliability projects. ABB provides long-term availability commitments and repair services.

ℹ️ Note: The AI810 is often confused with the AI815 (16-channel, non-HART) or AI845 (FOUNDATION Fieldbus). Confirm your order code: 3BSE008516R1 = AI810.

✅ Summary

The ABB AI810 delivers precision, flexibility, and intelligence for analog signal acquisition in demanding industrial environments. Its support for HART, redundancy, and deep System 800xA integration makes it a cornerstone of modern process automation—from refineries and power plants to water treatment and mining.