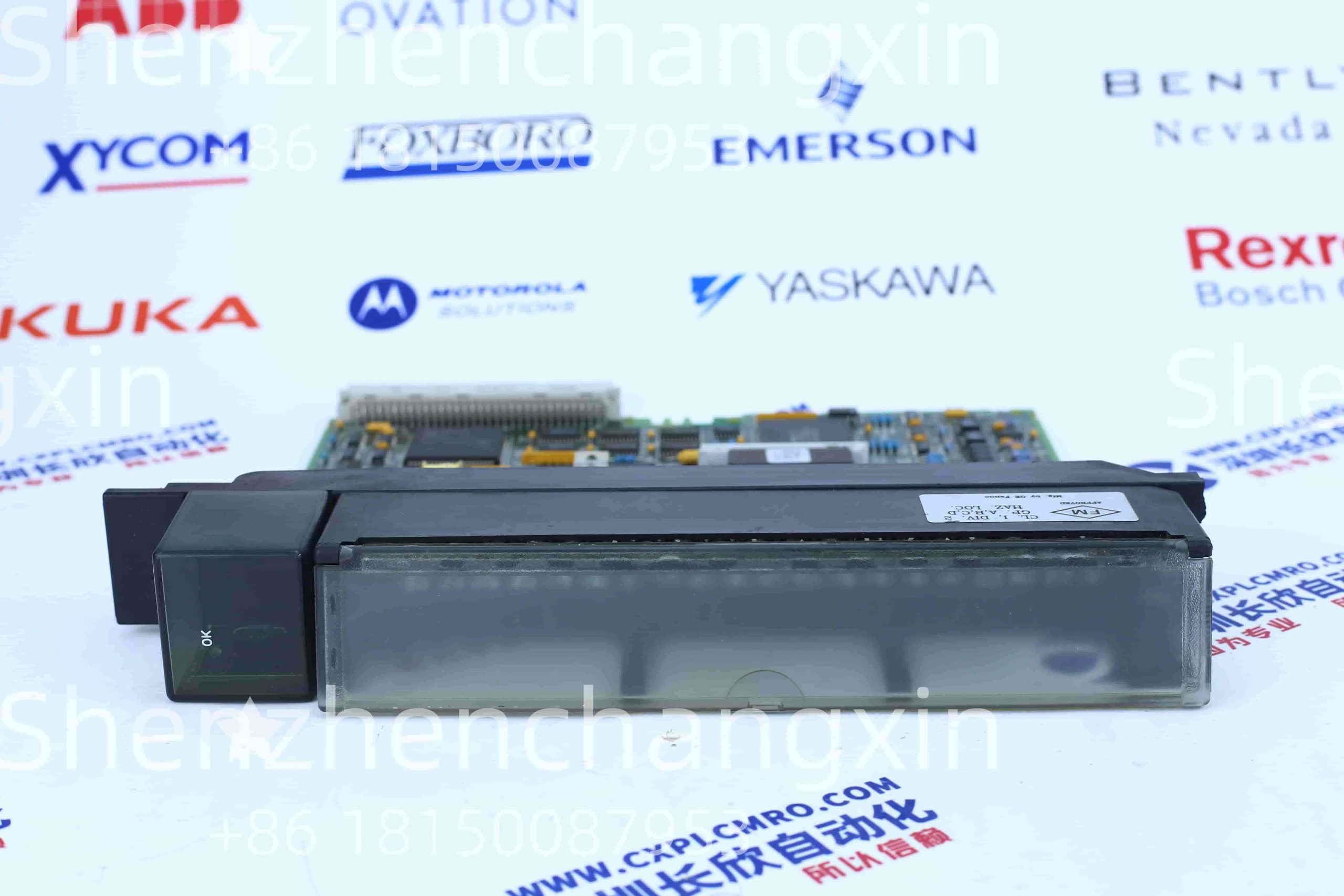

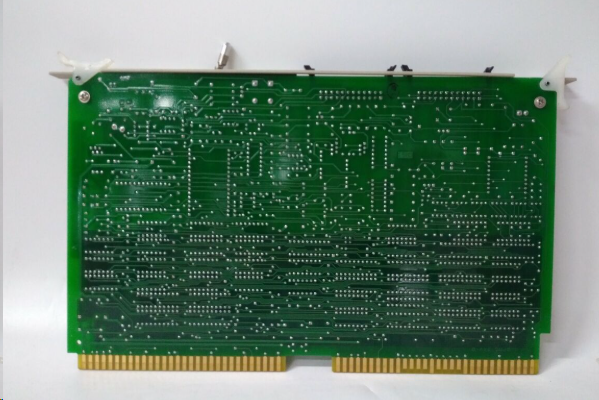

GE IC697ALG320 Analog Output Module

GE IC697ALG320 Analog Output Module

Product Overview

The GE IC697ALG320 is a high-performance analog output module manufactured by General Electric (GE), belonging to the GE Fanuc automation series. This module utilizes advanced industrial-grade design and is primarily used to convert digital signals into analog signals to drive actuators, valves, motors, and other analog devices. The module features high precision, high stability, and excellent anti-interference capabilities, and is widely used in industrial automation control systems in chemical, power, metallurgy, pharmaceutical, and other industries.

Main Technical Parameters

Parameter Category

Technical Specifications

Product Model

IC697ALG320

Manufacturer

GE (General Electric)

Product Type

Analog Output Module

Number of Output Channels

2 channels

Output Type

Voltage output or current output

Output Voltage Range

0-5V, 0-10V

Output Current Range

4-20mA, 0-20mA

Resolution

12-bit

Accuracy

±0.1% FSR (Full Scale Range)

Update Rate

100 times per second

Load Capacity

Voltage output: minimum 2kΩ

Current output: maximum 500Ω

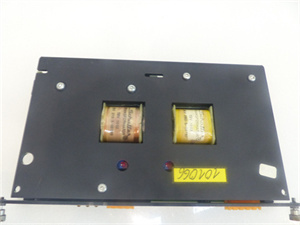

Isolation Method

Channel-to-channel isolation, channel-to-logic circuit isolation

Supply Voltage

24V DC

Operating Temperature

-20℃ to 70℃

Storage Temperature

-40℃ to 85℃

Protection Class

IP20

Core Functional Features

1. High-Precision Output Performance

The module adopts a 12-bit resolution design, ensuring the accuracy of the output signal and meeting the needs of precision control. The voltage output accuracy is ±0.1%, and the current output accuracy is ±0.2%, enabling high-precision analog control.

2. Flexible Configuration Options

Supports both voltage and current output types, with multiple output ranges available for each type (voltage: 0-5V, 0-10V; current: 4-20mA, 0-20mA). Users can flexibly configure the module according to actual application needs, adapting to different application scenarios.

3. Fast Response Capability

The module’s update rate reaches 100 times per second, ensuring the real-time and accuracy of the output signal and meeting the needs of high-speed control systems. 4. High Reliability Design

The design incorporates channel-to-channel isolation and channel-to-logic circuit isolation, effectively preventing signal interference and improving system stability and reliability. The module operates stably in a wide temperature range of -20℃ to 70℃, adapting to various harsh industrial environments.

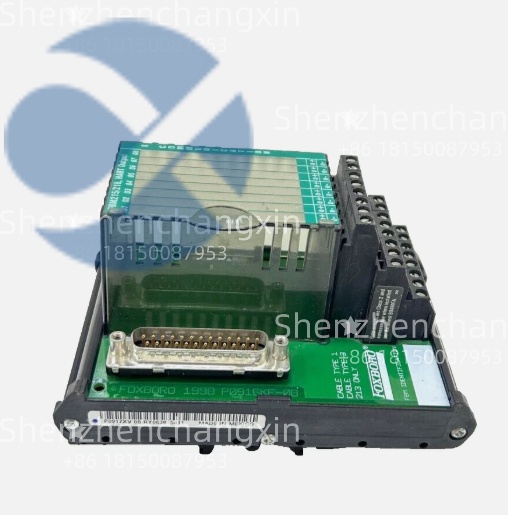

5. Easy Maintenance

Modular design with LED status indicators facilitates quick diagnosis and troubleshooting. Online configuration and parameter modification are supported, simplifying system maintenance and debugging.

Application Areas

The GE IC697ALG320 analog output module is widely used in the following industrial fields:

Chemical Production: Controlling parameters such as temperature and pressure of reaction vessels to ensure the stability and safety of chemical production processes.

Power Industry: Regulating the output voltage and current of generator sets to achieve stable operation of the power system.

Metallurgical Industry: Controlling parameters such as furnace temperature and material conveying speed to improve metallurgical production efficiency.

Pharmaceutical Industry: Controlling the operating parameters of pharmaceutical equipment to ensure the quality of drug production.

Manufacturing: Applied in production line automation control and equipment monitoring.

Water Treatment Systems: Real-time monitoring of analog signals such as water level and water pressure, and automatic control of water pump start/stop and operating frequency.

Product Advantages

High-precision control: 12-bit resolution with ±0.1% accuracy meets precision control requirements.

Flexible configuration: Supports multiple voltage and current output ranges to adapt to different application scenarios.

Fast response: 100 updates per second ensure real-time control performance.

High reliability: Isolation design and wide operating temperature range adapt to harsh industrial environments.

Easy maintenance: Modular design and status indicators facilitate quick diagnosis and troubleshooting.

Wide application: Suitable for various industries such as chemical, power, metallurgy, and pharmaceutical, meeting the needs of different scenarios.

With its advanced technology and reliable performance, the GE IC697ALG320 plays an important role in industrial automation control and is an ideal choice for building modern industrial control systems.

Choose Shenzhen Changxin, choose peace of mind, worry-free after-sales service! Large stock available, same-day SF Express shipping!!!