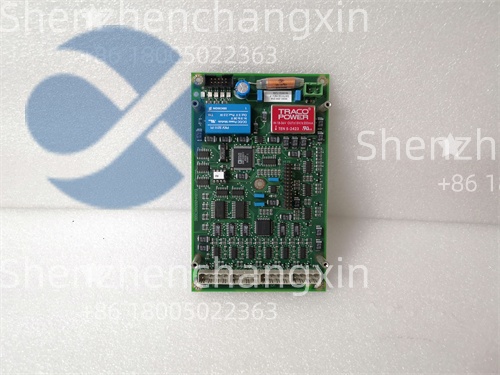

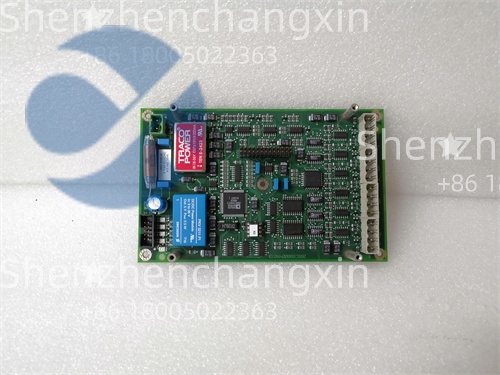

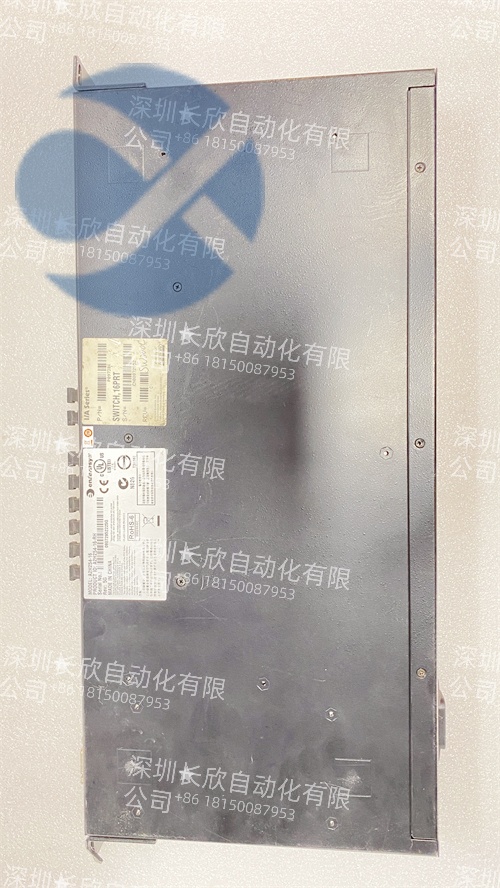

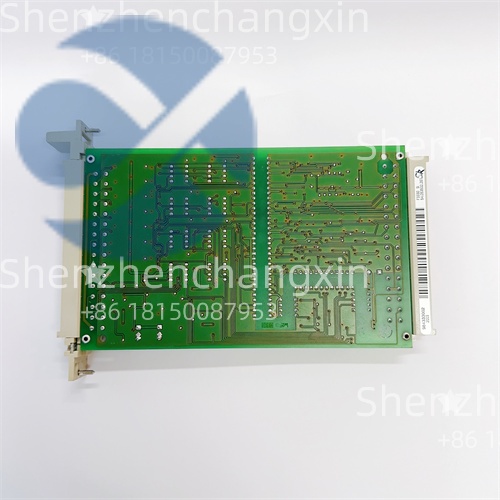

Schneider 140NRP31200C Module | Quantum NRP Series 24VDC Output Unit

Description

The SCHNEIDER 140NRP31200Cis a redundant power supply module manufactured by Schneider Electric for their Modicon Quantum automation platform.This specialized module provides reliable 24VDC power to Quantum PLC racks while offering hot-swappable redundancy capabilities for critical industrial applications.Designed for maximum system availability,it ensures uninterrupted power distribution to CPU,I/O,and communication modules in demanding automation environments.

Application Scenarios

In a large wastewater treatment plant’s central control system,the Modicon Quantum PLC manages critical processes including chemical dosing,pump control,and filtration.A power fluctuation occurs in one cabinet due to a transient surge.In a standard system,this could mean a complete PLC rack shutdown,potentially causing process upsets,environmental incidents,or equipment damage.However,with the SCHNEIDER 140NRP31200Cconfigured in a redundant pair,the system remains fully operational.The second,healthy power supply instantly takes over the full load without interruption.A maintenance technician can then safely remove and replace the faulty 140NRP31200Cmodule while the system continues to run,schedule the repair for the next shift change,and avoid a costly,unplanned process shutdown.This module directly addresses the critical need for maximum uptime in continuous process industries,power generation,and infrastructure systems where seconds of downtime translate to significant financial or safety consequences.

Parameter

Main Parameters

Value/Description

Product Model

140NRP31200C

Manufacturer

Schneider Electric

Product Category

Redundant Power Supply Module

Compatible System

Modicon Quantum Automation Platform

Input Voltage

120V AC(85-132V AC),47-63 Hz

Output Voltage

24V DC(Nominal)

Output Current

8A Maximum(at 40°C)

Redundancy Support

Yes,N+1 configuration with parallel operation

Hot-Swap Capable

Yes,for maintenance and replacement without shutdown

Status Indicators

OK LED(Green),Fault LED(Red)

Communication

Provides rack status to CPU via dedicated backplane signals

Mounting

Installs in Quantum power supply slots(left side of rack)

Key Feature

Current sharing and redundancy management for high availability systems.

Technical Principles and Innovative Values

The SCHNEIDER 140NRP31200Cimplements an active redundancy scheme that goes beyond simple parallel power supplies,providing true high-availability for mission-critical control systems.

Innovation Point 1:Intelligent Current Sharing&Load Balancing:Unlike basic redundant setups where a standby unit only activates after a failure,the 140NRP31200Coperates in a true N+1 active parallel configuration.Two modules share the total rack load equally through a current-sharing bus.This innovation prevents a single module from being over-stressed,extends its service life,and provides a seamless transition if one fails—there is zero transfer time as the healthy module is already carrying half the load and simply picks up the remainder.

Innovation Point 2:True Live Insertion and Removal(Hot-Swap):The module is engineered for live insertion and withdrawal,a critical feature for maintaining 24/7 operations.Special in-rush current limiting,staged connector mating,and intelligent slot detection circuitry allow a technician to safely remove a faulty unit or insert a replacement while the other power supply maintains system operation.This eliminates planned downtime for power supply maintenance.

Innovation Point 3:Comprehensive Diagnostics and Communication:The module provides more than just basic OK/Fault LEDs.It communicates its status(output voltage,load share,temperature)to the Quantum CPU via the rack’s dedicated communication channels.This allows for predictive maintenance—the PLC can log warnings if a power supply’s output begins to drift or if it is carrying a disproportionate share of the load,signaling potential issues before they cause a fault.

Innovation Point 4:The module operates on a master/slave communication principle when in a redundant pair.They communicate via a dedicated cable to coordinate current sharing and fault monitoring.If the master fails,the slave automatically assumes control.Its robust design includes protection against over-voltage,over-current,and over-temperature conditions,safeguarding not only itself but the expensive modules in the rack.

Application Cases and Industry Value

Case Study:Power System Reliability in a Natural Gas Compression Station

A remote natural gas compressor station,operating unmanned for extended periods,relied on a Modicon Quantum PLC for critical control of turbine speeds,valve sequences,and safety shutdowns.The existing single power supply was a single point of failure;its failure would lead to an uncontrolled station shutdown,potential gas flow disruption,and a costly emergency service call.The station was upgraded with a redundant power configuration using two SCHNEIDER 140NRP31200Cmodules.

Process&Improvement:The two 140NRP31200Cunits were installed in the redundant slots of the Quantum rack.They were connected via the redundancy cable and configured.During operation,the system automatically balanced the load.Several months later,during a severe thunderstorm,a voltage spike damaged one of the power supplies.The system seamlessly transferred the full load to the remaining unit without a single scan cycle interruption.The CPU reported the fault via the station’s telemetry system.Operators scheduled a replacement module to be installed during the next routine site visit,avoiding an estimated 12 hours of downtime and potential revenue loss exceeding$50,000.The control engineer stated,”The 140NRP31200Credundancy turned a potential major incident into a minor maintenance note.The system’s self-diagnosis and hot-swap capability are exactly what we need for remote,critical infrastructure.”

Related Product Combination Solutions

The SCHNEIDER 140NRP31200Cis a component within a comprehensive high-availability system.Its functionality is intertwined with other Quantum components:

140CPU65150:Modicon Quantum CPU.The power supply provides clean,stable 24VDC to this processor.The CPU,in turn,monitors the health status of the 140NRP31200Cvia the backplane.

140CPS11420:The 24VDC CPS(Compact Power Supply)for the rack.The 140NRP31200Ctypically powers the CPS,which then distributes power to all other modules.They work in tandem.

140XBP00600:A Quantum 6-slot local baseplate.The 140NRP31200Cmodules install directly into the dedicated power supply slots on this(or similar)baseplate.

140NOE77111:Network Option Module(Ethernet).This communication module,powered by the rail fed by the 140NRP31200C,allows the CPU to send power supply diagnostic alerts over the network to a SCADA system.

140CRP93200:A differentredundant power supply(e.g.,240VAC input).It’s crucial to select the correct input voltage variant(140NRP31200Cfor 120VAC)for your plant’s electrical system.

140PSU31000:A standard(non-redundant)24V power supply.The 140NRP31200Cis the high-availability upgrade from this type of unit.

TSXPWR3525:A power supply for the smaller Modicon M340 platform.This is for a different Schneider PLC family,illustrating the importance of platform-specific compatibility.

Installation,Maintenance,and Full-Cycle Support

Installation of the SCHNEIDER 140NRP31200Crequires careful planning.The module is designed to be installed in the dedicated power supply slots on the left side of a Quantum rack.For redundant operation,two modules are installed,and the mandatory redundancy communication cable must be connected between them.The AC power input wiring must be performed by a qualified electrician following local codes,and it is critical to ensure the input voltage matches the module’s rating(120VAC for the 140NRP31200C).The DC output connectors snap into the backplane to power the rack.Proper grounding of the chassis is essential for noise immunity and safety.

Maintenance is greatly simplified by the module’s hot-swap capability and diagnostics.Routine tasks involve visually checking the status LEDs(Green OK,Red Fault)and ensuring the cooling vents are unobstructed.The most common proactive maintenance is the replacement of an aging unit or a module showing pre-fault warnings via the PLC diagnostics.The hot-swap feature allows this to be done during normal production.

We provide comprehensive support for the SCHNEIDER 140NRP31200C.Every unit we supply undergoes testing to verify input/output voltage regulation,current sharing capability(if tested in a pair),and proper LED sequencing.We can provide technical guidance on integrating this module into new or existing Quantum racks for redundancy.Our commitment is to deliver a mission-critical component that meets Schneider’s original specifications,backed by expert knowledge to help you achieve the system availability your process demands.Ensure your critical automation never skips a beat.Contact us for a reliable redundant power solution tailored to your Quantum system.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!