HONEYWELL TC-ODK161: 16-Channel Discrete Output Module

Description:

The HONEYWELL TC-ODK161is a 16-channel discrete(digital)output module designed for the Experion Process Knowledge System(PKS)C Series I/O.It functions as a critical interface,converting control signals from the Experion controllers into physical on/off commands to activate field devices such as solenoid valves,motor starters,pumps,and alarms within a process automation environment.

Application Scenarios:

In a large wastewater treatment plant,the automated control of dozens of chlorine dosing valves,filter backwash pumps,and alarm indicators is essential.The plant’s Experion PKS controller determines when a specific pump needs to start.This logical command is sent via the control network.The HONEYWELL TC-ODK161module,housed in a remote I/O marshalling cabinet near the filter beds,receives this command.One of its 16 output channels energizes,sending 120V AC power to the coil of the pump’s motor starter contactor.The contactor closes,starting the pump.This application of the TC-ODK161provides the vital,reliable link between the digital control system’s logic and the physical action in the field,enabling precise and automated process control across vast industrial facilities.

Parameter:

Main Parameters

Value/Description

Product Model

TC-ODK161

Manufacturer

Honeywell

Product Category

Discrete Output(DO)Module/I/O Card

Compatible System

Honeywell Experion PKS C Series I/O

Number of Channels

16 discrete outputs

Output Type

Triac(Solid-State)switching elements

Output Voltage

120V AC

Current Rating per Channel

0.5 A continuous

Point-per-Point Isolation

Channel-to-channel and channel-to-logic isolation

Status Indication

LED per channel(Output On,Fault)

Communication

Interfaces via the C Series I/O bus to the Field Bus Module(FBM)

Connection

Front-removable terminal block for field wiring

Mounting

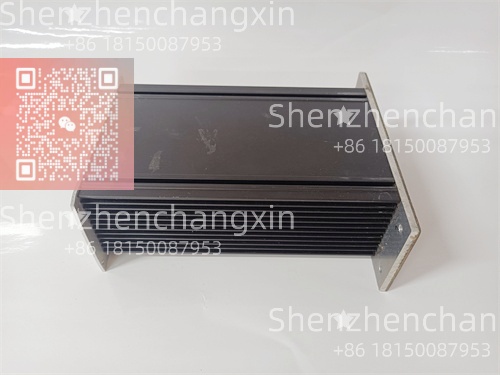

Plugs into a C Series I/O carrier plate within a DIN rail mountable assembly

Technical Principles and Innovative Values:

Innovation Point 1:High-Density,Solid-State Reliability.The TC-ODK161packs 16 individually isolated output channels into a single,compact module.It utilizes solid-state Triac switches instead of electromechanical relays.Triacs have no moving parts,resulting in silent operation,extremely fast switching speeds(enabling rapid control sequences),and a vastly longer operational life—typically hundreds of millions of cycles.This makes the module ideal for applications requiring frequent on/off cycling,such as batch processes or alarm signaling,where a mechanical relay would quickly wear out.

Innovation Point 2:Comprehensive Fault Diagnostics and Point Isolation.Each channel is equipped with LED indicators providing immediate visual status of the output state.More importantly,the module features sophisticated fault detection circuitry.It can diagnose and report conditions like open load(broken wire)or short-circuit on a per-channel basis back to the Experion control system.This allows operators to be proactively alerted to field wiring issues before they cause process upsets.The point-per-point isolation prevents a fault on one channel(e.g.,a short circuit)from affecting any other channel or the control system logic,ensuring fault containment and overall system resilience.

Innovation Point 3:Hot-Swappable Design for Maximum Uptime.Designed for critical process environments,the TC-ODK161and the entire C Series I/O platform support hot-swapping under certain conditions.This means a faulty module can be replaced without requiring a full shutdown of the associated process loop or the entire control system.An engineer can remove the module by releasing the terminal block and extracting the unit,then insert a new one.The system automatically recognizes the new hardware and downloads the configuration,minimizing process interruption and supporting exceptional plant availability.

Application Cases and Industry Value:

Case Study:Pharmaceutical Cleanroom Environmental Control.A biotech facility requires ultra-precise control of room pressure cascades to prevent cross-contamination.Dozens of motorized dampers and variable fan drives must actuate based on differential pressure sensor readings.

The facility’s control system,centered on a Honeywell Experion PKS,uses multiple TC-ODK161modules distributed in panels near the air handling units.Each module controls a group of damper actuators(on/off for isolation)and provides start/stop signals to fan system components.The solid-state reliability of the TC-ODK161is critical,as these outputs cycle frequently to maintain pressure.During a scheduled test,a short circuit was induced on one damper actuator wire.The specific channel on the TC-ODK161immediately detected the fault,de-energized safely,and sent a precise diagnostic alarm to the control room,identifying the exact damper.Maintenance resolved the issue within the hour without any impact on the cleanroom’s validated state.The facility’s engineering team highlighted the module’s diagnostic capability and rock-solid reliability as key to maintaining their strict FDA-compliant environmental conditions.

Related Product Combination Solutions:

The TC-ODK161is one component in the Experion C Series I/O family.Key related products include:

Field Bus Module(e.g.,TC-FLOx):The communication head that manages a group of I/O modules like the TC-ODK161and interfaces with the Experion controller.

Carrier/Baseplate(e.g.,for C Series I/O):The physical mounting unit that provides power and data bus connection for the I/O modules.

Discrete Input Modules(e.g.,TC-IDK161):16-channel input cards for reading field switch and contact status,often used in conjunction with output modules.

Analog I/O Modules(e.g.,TC-AAI161,TC-AOI161):For interfacing with 4-20mA or voltage signals from transmitters and to valve positioners.

Redundant Power Supply:Ensures continuous operation for critical I/O groups.

Experion Control Software:The configuration,programming,and monitoring environment where the points for the TC-ODK161are defined and logic is created.

Honeywell Termination Panels:Pre-wired marshalling cabinets designed to neatly organize field wiring connections to the I/O modules.

Installation,Maintenance,and Full-Cycle Support:

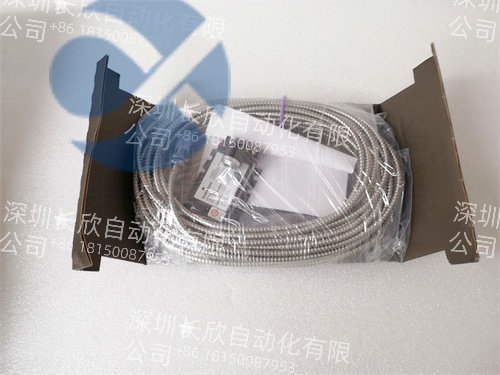

Installation involves mounting the C Series carrier on a DIN rail,plugging the TC-ODK161module into its assigned slot,and securing the front-terminal block.Field wiring for the 120V AC load connections is then landed on this block.Configuration is performed entirely within the Experion control software,where each channel is assigned a tag name,aligned with the control logic,and placed into service.The hot-swap capability is a key installation and maintenance feature.

Routine maintenance involves periodic visual inspection of LED status indicators and reviewing system diagnostics for any reported faults.The solid-state design requires no periodic calibration.If a module fault is indicated,the hot-swap procedure allows for replacement with minimal downtime:the new module is inserted,and the system automatically recognizes it and applies the stored configuration.We provide end-to-end support for the TC-ODK161.Our modules are sourced from certified supply chains.Prior to shipment,each unit undergoes functional testing to verify channel operation and LED functionality.We offer technical expertise for integration planning and troubleshooting,supporting the long-term reliability of your Experion PKS infrastructure.

UFC921A101 3BHB024855R0101 UFC911B106 3BHE037864R0106 UDC920BE01 3BHE034863R0001 XVC770BE101 3BHE021083R0101 KUC755AE105 3BHB005243R0105 LXN1604-6 3BHL000986P7000 LWN2660-6E 3BHL000986P7002 UFC789AE 38HE014022P102 3BHL000734P0003 SLOV4.6/5.3 HIES308461R0012 HIES208441R.. ID8A92485001/022 3BHB009410R000 SG000247 3BHL000986P1006 XVC724BE101 3BHE009017R0102 DKTFM418B 3BHB015651P0001 PU180/63E 3BHB00916230001 HIES308461R0012 FPX86-9345–B 3BHL000986P0006 3BHL000734P0003 SLOV4.6/5.3 UFC921A101 3BHE024855R0101 PPC907BE101 3BHE024577R0101 XVC724BE101 3BHE009017R0102 IEC60129,62271-102 MI-CONP KUC755AE105 3BHB005243R0105 HIES308461R0012 MG160MD2-42FF300-F1 PTC 160℃ TP211 MG160MD2-42FF300-F1 ABB S-073N ALU 3BHB009884R5211 ABB S-093H 3BHB030478R0309 ABB S-123H 3BHB030479R0512 ABB UFC912A101 3BHE039426R0101 ABB 5SHY4045L0001 3BHB018162R0001 ABB S-113N 3BHB018008R0001 W4 KUC755AE105 3BHB005243R0105 HIEE401807R0001 3BHB046719R0008 STRAUB FLEX1L TB820V2 S-053M 3BHB012897R003 *12 3BHB014556R0001 3BHB010823R0002 CDP312R XVC768AE102 UFC789AE101 S-073N KU C755AE105 XVC770BE101 UFC760BE42 PPC907BE UFC760BE43 XVC769AE101 LDMTR-01 UAC389AE02 LTC391AE01 PPC905AE101 UAC383AE01 LDLPTR-01